Top 10 Benefits of the Injection Moulding Process You Need to Know

The injection moulding process has become a cornerstone in the manufacturing industry, allowing for the efficient production of complex parts with high precision. According to Dr. Linda Matthews, a leading expert in polymer engineering, "The injection moulding process not only enhances production efficiency but also ensures a level of consistency that is hard to achieve through traditional manufacturing means." This statement underscores the significance of injection moulding in today's fast-paced production environments.

With a plethora of benefits that encompass cost-effectiveness, design flexibility, and reduced waste, understanding the advantages of the injection moulding process is crucial for businesses looking to optimize their operations. As industries continue to evolve and demand for high-quality components increases, the injection moulding process remains a pivotal technique that can significantly improve production capabilities. In the following sections, we will delve into the top ten benefits of this remarkable manufacturing method, shedding light on why it remains indispensable in various sectors.

Benefits of Injection Moulding: An Overview

The injection moulding process is a highly efficient manufacturing method that offers numerous advantages across various industries. One of the key benefits is its ability to produce complex shapes with high precision, ensuring that each component meets strict tolerances. This capability not only enhances product quality but also reduces waste, making it an environmentally friendly option. Furthermore, injection moulding can be scaled for mass production, significantly lowering the cost per unit as the volume increases.

Tips: When considering injection moulding, it's crucial to design parts with manufacturability in mind. This means opting for geometries that can be easily produced without excessive post-processing. Additionally, selecting the right material can greatly affect the performance and longevity of the finished product.

Another significant advantage of injection moulding is its speed. The process can produce a large number of parts in a short amount of time, allowing businesses to meet tight deadlines and rapidly respond to market demands. Moreover, with advancements in technology, the efficiency of the moulding machines continues to improve, leading to further reductions in cycle times and costs.

Tips: Collaborating with experienced professionals during the design phase can help optimize production efficiency. Early engagement can identify potential issues and streamline the entire process, ensuring that the benefits of injection moulding are fully realized.

Cost Efficiency in Large Scale Production

The injection moulding process is widely recognized for its ability to achieve cost efficiency in large scale production. This manufacturing method allows for the mass production of complex shapes with high precision and repeatability, making it ideal for industries that require consistent quality over thousands of units. By utilizing a single mould to produce numerous parts simultaneously, manufacturers can significantly reduce the per-unit cost, leading to substantial savings when operating at large scales.

Additionally, the efficiency of the injection moulding process extends beyond just the production of the items themselves. The speed at which parts can be produced means that overall lead times for projects are drastically shortened. This rapid production capability not only meets high demand but also reduces inventory costs, as manufacturers can produce just in time for their needs. Furthermore, the process minimizes waste through its ability to rehearse and recycle materials, contributing further to cost efficiency in large scale manufacturing scenarios.

Overall, the injection moulding process stands as a cornerstone of modern production methods, offering remarkable economic advantages that can propel businesses forward.

Design Flexibility and Complexity Benefits

The injection moulding process is renowned for its exceptional design flexibility and ability to produce complex geometries, making it a preferred choice for various industries. One of the primary benefits of this manufacturing technique is the capability to create intricate designs that would be difficult or impossible to achieve through traditional methods. With advanced computer-aided design (CAD) technology, engineers can develop highly detailed parts that incorporate complex features, such as undercuts, textures, and internal structures. This complexity not only enhances the functionality of the product but also allows for innovative shapes that improve aesthetic appeal.

Moreover, injection moulding supports the efficient production of custom parts in high volumes while maintaining tight tolerances. The process enables the use of multiple materials in a single component, allowing for combinations of rigidity, flexibility, and coloration that can be tailored to specific applications. As a result, designers have the freedom to explore new ideas without the constraints typically associated with other manufacturing techniques. This flexibility not only accelerates the product development cycle but also makes it easier to iterate and refine designs based on feedback, ultimately leading to superior end products.

Top 10 Benefits of the Injection Moulding Process

Enhanced Product Consistency and Quality

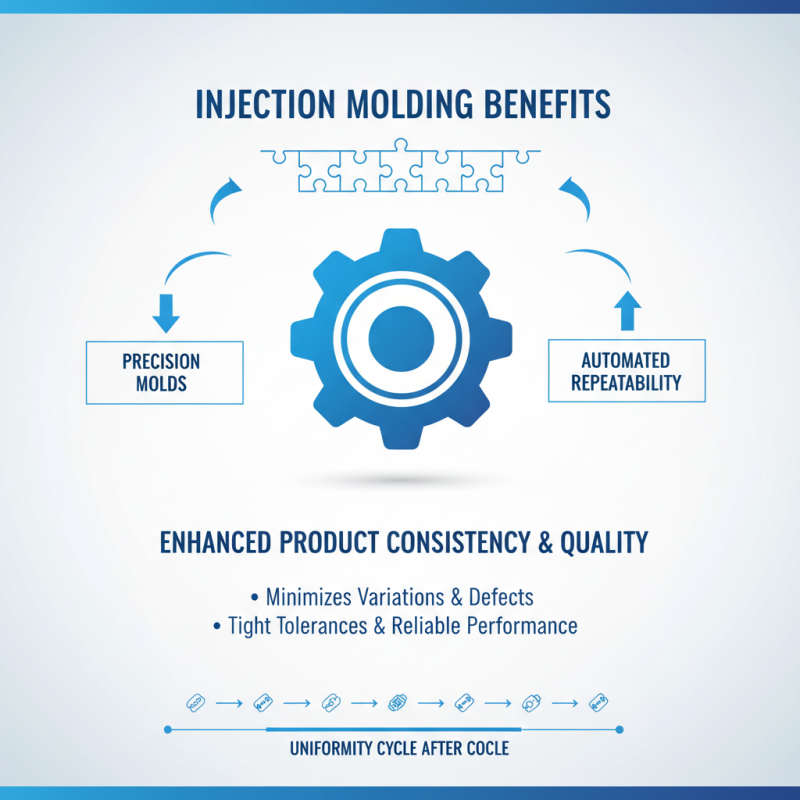

One of the most significant benefits of the injection moulding process is its ability to ensure enhanced product consistency and quality. This manufacturing technique utilizes precision molds to produce parts that are nearly identical, minimizing variations and defects. The automated nature of the injection moulding process allows for high repeatability in production, which is crucial for industries that demand tight tolerances and dependable performance. With each cycle, the material is injected into the mold with consistent pressure and temperature, leading to uniformity in the final product.

Furthermore, injection moulding enables the use of high-quality materials that can be molded into complex shapes and designs. The process allows for the integration of various additives that can enhance strength, flexibility, and other desirable properties of the product. This capability not only improves the overall quality but also increases the lifespan and reliability of the final goods. As a result, manufacturers can produce items that consistently meet or exceed industry standards, ensuring customer satisfaction and fostering brand loyalty.

Reduced Waste in Manufacturing Processes

The injection moulding process is renowned for its efficiency and precision, making it a preferred choice in manufacturing across various industries. One of the significant benefits it offers is the reduction of waste during production. According to a report by the American Society of Plastics Engineers (ASPE), injection moulding can achieve material utilization rates of over 90%, drastically minimizing scrap and excess material compared to traditional manufacturing methods. This high efficiency is primarily due to the process's ability to create complex shapes with minimal excess material.

Moreover, the controlled environment of injection moulding allows for better recycling and reuse of materials. A study published by Plastics Technology highlights that advancements in technology have enabled the recycling of post-industrial and post-consumer plastics into raw materials for injection moulding, further enhancing sustainability in manufacturing. With this ability to recycle materials effectively, companies can not only decrease their operational costs but also adhere to growing environmental regulations and consumer expectations regarding sustainability. This dual advantage positions injection moulding as a leader in reducing manufacturing waste, thus benefiting both businesses and the environment.

Related Posts

-

Exploring the Role of Import and Export Certifications in Best Mold Manufacturing

-

Leveraging Excellent After Sales Support for Cost Effective Future of Best Mold Design in Injection Molding

-

Unlocking the Secrets of Best Plastic Manufacturing with Comprehensive Technical Guidelines

-

Innovative Examples of Automotive Injection Molding Applications in the Industry

-

In Depth Comparison of Plastic Injection Mold Tooling Techniques and Their Industry Impact

-

What is the Impact of Medical Injection Molding on Healthcare Innovation and Patient Outcomes