How to Choose the Right Medical Injection Molding Process?

Choosing the right medical injection molding process is crucial for the healthcare industry. The global medical injection molding market was valued at approximately $6 billion in 2021 and is expected to grow significantly. This growth reflects the increasing demand for high-quality medical devices and components.

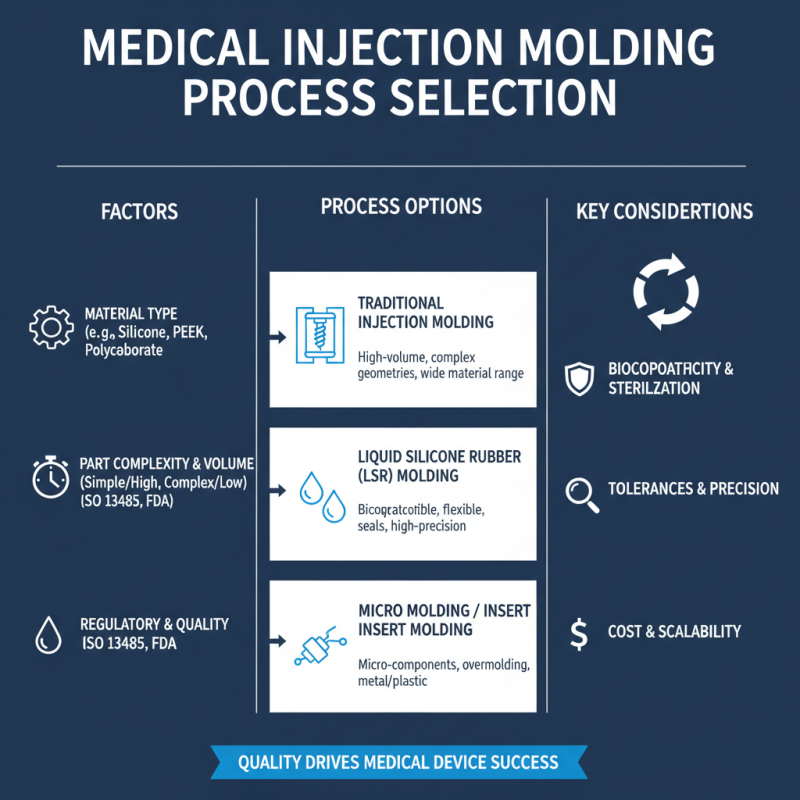

Medical injection molding provides precision and efficiency for manufacturing complex shapes. It’s essential to consider the material, design, and production volume. Each choice directly impacts product quality and cost. Companies must reflect on the capabilities of each process. For instance, thermoplastics are popular for their versatility, while silicone offers flexibility.

Understanding these factors can be challenging. The wrong decision may lead to defective products that could jeopardize patient safety. Each error carries lasting consequences. Therefore, a thorough evaluation of each option is necessary. It’s a process that requires careful thought and adjustment.

Understanding Medical Injection Molding Processes and Their Applications

Medical injection molding is essential in the healthcare industry. Different processes serve various applications. Understanding these processes can lead to better decision-making.

There are several medical injection molding techniques. For instance, traditional injection molding is widely used for producing precise parts. This method is reliable but may face challenges in material selection. In contrast, micro-injection molding offers high precision, suitable for small components. However, it can be costly and requires specialized equipment. Evaluating these options is crucial in determining the right solution.

Another important aspect is compliance with regulations. Many processes must adhere to strict industry standards. This can complicate production timelines. Additionally, not all manufacturers have the expertise to navigate these complexities. It's vital to consider production capabilities and limitations before choosing a method. Sometimes, the faster option may not be the best one in the long run. Taking the time to reflect on these factors can lead to better outcomes.

How to Choose the Right Medical Injection Molding Process? - Understanding Medical Injection Molding Processes and Their Applications

| Process Type | Materials Used | Advantages | Applications |

|---|---|---|---|

| Standard Injection Molding | PP, ABS, PVC | High production rates, Cost-effective | Medical devices, Syringe bodies |

| Multi-Material Injection Molding | Silicone, TPU | Enhanced functionality, Customization | Complex medical instruments |

| Insert Molding | Polycarbonate, Nylon | Space-saving designs, Sealing components | Electronics in medical devices |

| Blow Molding | HDPE, PET | Lightweight, Large hollow parts | Medical containers, Bottles |

| 3D Printing | PLA, ABS | Rapid prototyping, Complex designs | Custom implants, Surgical guides |

Key Factors Influencing the Selection of Injection Molding Techniques

Choosing the right medical injection molding process is critical. Several key factors impact this selection. Understanding these factors helps ensure the production of high-quality medical devices.

Material compatibility is fundamental. Different materials have unique properties. You must match the material to the intended use. Consider factors like biocompatibility. Some materials may interact negatively with medications. Improper selection could lead to potential harm.

Design complexity also plays a role. Simpler designs often lead to cost-effective processes. However, intricate designs may require advanced molding techniques. Evaluate how the design affects manufacturability. It's also essential to consider the production volume. High-volume runs might justify extra investments in specialized equipment.

**Tips:** Always prototype before full production. This can reveal design flaws early. Consider consulting with experts during the process. Their insights can prevent costly mistakes down the line. Lastly, never overlook the importance of regulatory compliance. Every medical device must meet strict standards. Ignoring this can lead to significant setbacks.

Comparative Analysis of Various Injection Molding Technologies

Choosing the right medical injection molding process requires careful consideration of various technologies. Different methods serve unique purposes. For instance, traditional injection molding is commonly used for large-scale production, offering high efficiency. In contrast, rapid injection molding caters to prototype development, speeding up the design process significantly.

Other techniques, like micro-injection molding, are essential for creating tiny components. These components often relate to critical medical instruments. However, the complexity of these methods can lead to challenges. Sometimes, achieving precision may not be as simple as expected. This can result in delays and increased costs during production.

3D printing is an emerging technology that offers flexibility. It allows for quick adjustments and customization. However, it may not always meet regulatory standards for medical devices. Manufacturers must weigh the pros and cons of each process. The decision is not straightforward and requires extensive research and testing. Each option has merits and possible drawbacks that must be thoroughly analyzed.

Evaluating Material Compatibility for Medical Injection Molding

Choosing the right material is crucial for medical injection molding. Compatibility significantly impacts the performance and safety of medical devices. Various polymers are available, but not all work well in every application. Factors like biocompatibility and mechanical properties must be considered.

Materials need to withstand sterilization processes. They should not degrade or leach harmful substances. Some resins are excellent for flexibility but may lack strength. Others excel in rigidity but may not be safe for body contact. Understanding these trade-offs is essential for successful product development.

Testing material compatibility is often overlooked. Manufacturers sometimes assume materials will perform similarly. This can lead to catastrophic failures in critical applications. Inconsistent results during processing can also indicate a material mismatch. Comprehensive evaluations should be a standard practice to minimize risks and ensure quality.

Cost Considerations and Production Scalability in Injection Molding Choices

When selecting a medical injection molding process, cost considerations play a crucial role. The total production cost can significantly vary based on the chosen materials and technology. For instance, silicone-based materials often incur higher expenses due to their specialized properties. A recent industry report indicates that production costs might increase by up to 30% when employing advanced materials for precision medical devices. This shift can impact pricing strategies and profit margins.

Production scalability is another key factor. Efficient processes allow manufacturers to ramp up production without sacrificing quality. For example, utilizing automated systems can enhance throughput. A study from a leading industry association revealed that automation can increase output by nearly 50% in some cases. However, mastering these technologies demands an upfront investment, which can be daunting for smaller companies. Additionally, the consistency of molded parts must be monitored closely to avoid waste and defects.

Choosing the right process is not just about immediate costs. It involves assessing long-term viability and growth potential. Some companies struggle to find balance in scaling production while remaining cost-effective. The dynamic market for medical devices requires ongoing evaluation of both production capabilities and economic factors. Flexibility in manufacturing decisions can lead to better adaptation to market demands, but not all firms are prepared for this challenge. These considerations should influence the final choice in the injection molding process.

Related Posts

-

Leading Chinese Factory Delivers Unmatched Excellence in Medical Injection Molding

-

Innovative Examples of Automotive Injection Molding Applications in the Industry

-

What is the Impact of Medical Injection Molding on Healthcare Innovation and Patient Outcomes

-

How to Optimize Injection Molding Tolerances for Enhanced Product Quality and Precision

-

Exploring the Role of Import and Export Certifications in Best Mold Manufacturing

-

5 Expert Tips for Optimizing Your Metal Injection Mold Design