Common Issues in Achieving the Best Plastic Injection Mold Design

In the fast-paced world of manufacturing, the significance of effective plastic injection mold design cannot be overstated. According to a report by Grand View Research, the global injection molding market is expected to reach $338.41 billion by 2025, driven largely by the increasing demand for lightweight and durable materials across various industries. However, achieving the best design is fraught with challenges, particularly concerning after-sales service advantages and maintenance costs. A well-engineered mold can enhance manufacturing efficiency and reduce production costs, but if not properly supported by robust after-sales service, the initial investment may not yield the desired returns. This blog explores common issues encountered in plastic injection mold design, highlights the importance of a strategic maintenance plan, and provides actionable insights on how to optimize both design and service for cost-effective, long-lasting solutions in the manufacturing process.

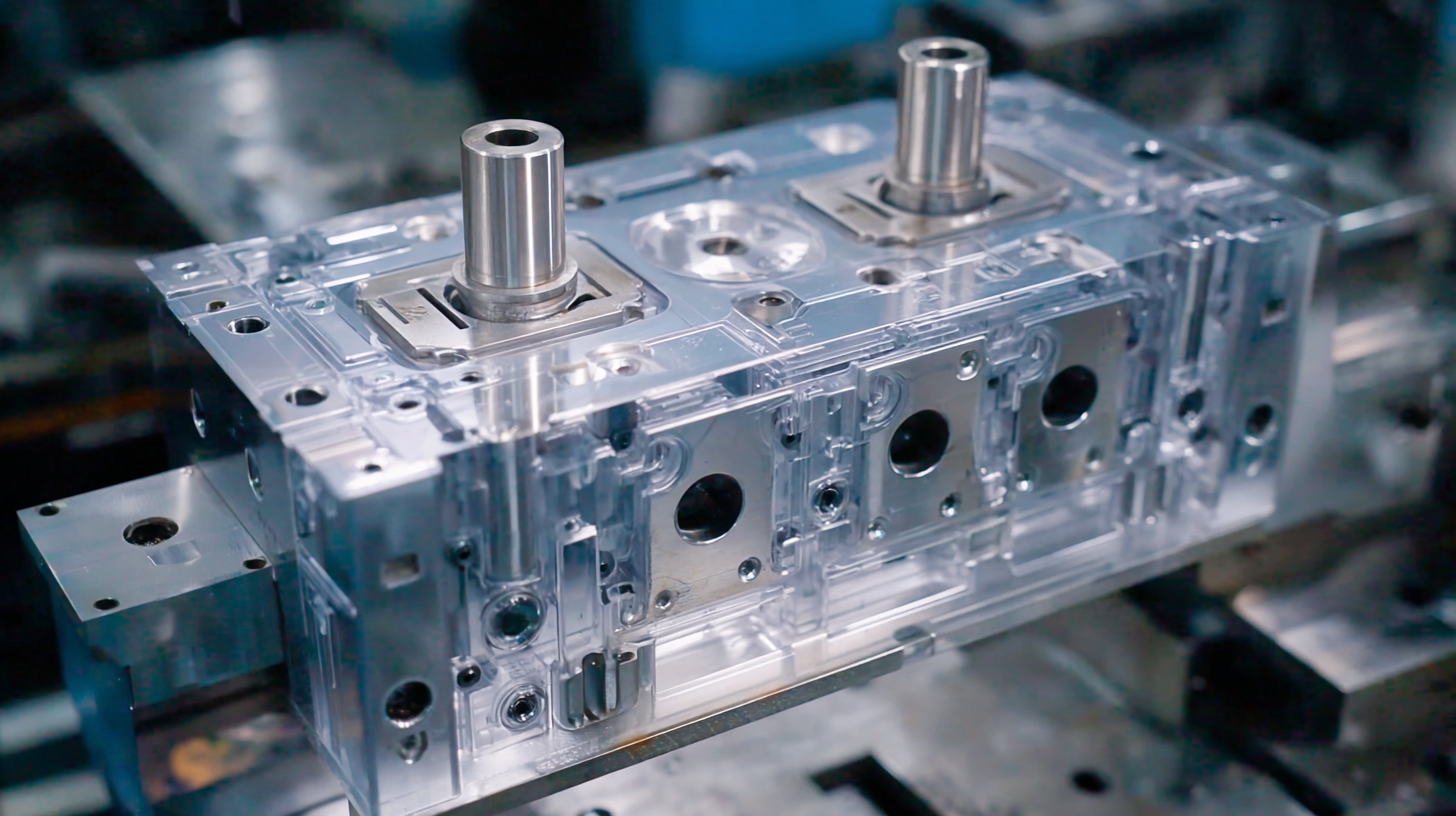

Understanding the Importance of Precision in Plastic Injection Mold Design

Precision in plastic injection mold design is crucial for ensuring the quality and performance of the final product. When molds are designed with exact measurements and tight tolerances, it minimizes the likelihood of defects such as misaligned features, inconsistent wall thickness, and surface imperfections. These flaws can not only compromise the integrity of the plastic parts but also lead to increased production costs and time delays due to rework and scrap.

Moreover, achieving precision in mold design requires a deep understanding of the materials and processes involved. Factors such as material shrinkage, temperature variations, and pressure adjustments must be meticulously accounted for during the design phase. Employing advanced techniques like computer-aided design (CAD) and simulations can enhance precision, enabling designers to visualize potential issues before they manifest on the production floor. By prioritizing precision, manufacturers can enhance efficiency, reduce waste, and ultimately produce higher-quality plastic products that meet customer demands.

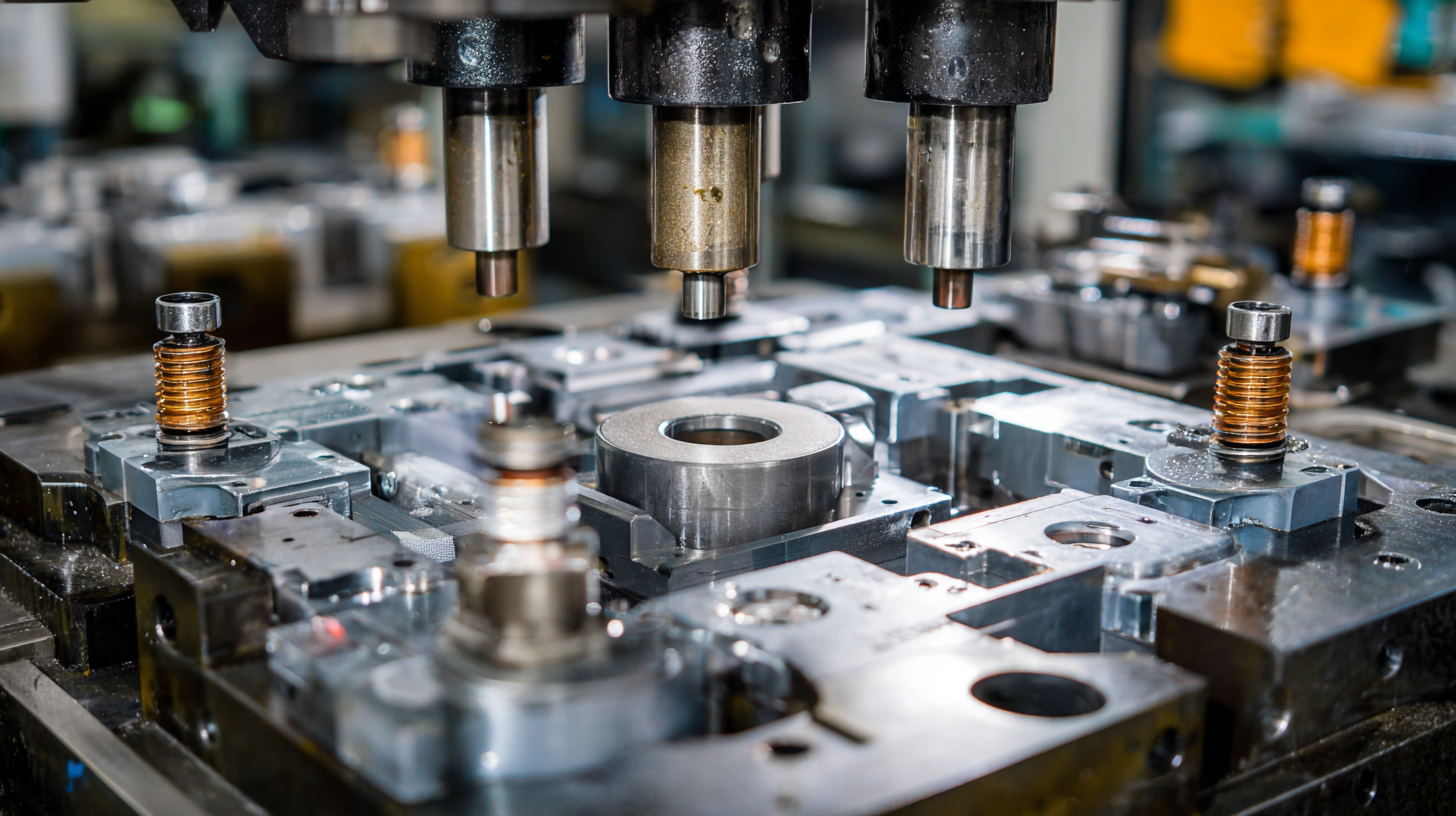

Identifying Common Design Flaws in Plastic Injection Molds

When it comes to plastic injection mold design, identifying common design flaws is crucial for achieving optimal product quality. One of the primary issues faced by designers is the lack of proper cooling channel placement, which can lead to uneven cooling and warping of the final product. This not only affects the dimensional accuracy but can also lead to defects such as sink marks or surface blemishes, which are detrimental to the aesthetics and functionality of the moldings.

Another common flaw is improper venting, which can result in air traps within the mold. These trapped air pockets can compromise the integrity of the molded parts, leading to cosmetic defects and structural weaknesses. It is essential for designers to incorporate effective venting strategies to ensure air is expelled during the injection process, promoting uniform fill and preventing defects. By addressing these design flaws, manufacturers can significantly enhance the performance and reliability of their injection molds, paving the way for superior quality products.

Overcoming Material Selection Challenges for Optimal Mold Performance

When it comes to plastic injection mold design, one of the most significant challenges is material selection. The choice of material can greatly influence the mold's performance, longevity, and the quality of the final product. Various factors such as thermal conductivity, wear resistance, and cost need to be considered when selecting materials.

For instance, using a material that can withstand high temperatures is essential for maintaining the integrity of the mold during the injection process.

Moreover, different applications may require unique characteristics that not all materials can provide. In many cases, engineers are faced with the dilemma of balancing performance with budget constraints. This often leads to innovative material solutions, such as the use of composites or modified steels, which can offer enhanced properties at a reasonable cost.

Understanding the specific requirements of the molding process and the end-use of the product is vital in overcoming these challenges, ensuring that the selected material will not only perform optimally but also provide a competitive edge in the marketplace.

Addressing Cooling and Heating Issues in Mold Design

Achieving optimal cooling and heating in plastic injection mold design is crucial for enhancing production efficiency and ensuring part quality. According to a recent industry report by the Plastics Industry Association, improper temperature control can reduce cycle times by up to 30%, significantly impacting production throughput. The report emphasizes that maintaining uniform temperatures across the mold surface is essential, as thermal gradients can lead to warping and defects in the final product.

Furthermore, advanced cooling technologies, such as conformal cooling channels, have been shown to improve heat transfer efficiency, resulting in faster cooling cycles and reduced energy consumption. The Society of Plastics Engineers indicates that molds equipped with such technologies can decrease cooling time by 20-50%. Implementing robust heating systems is equally important; precise control of mold temperatures can enhance material flow and surface finish, thereby minimizing the risk of defects like sink marks or short shots. By addressing these critical factors, manufacturers can achieve a more reliable and efficient injection molding process, ultimately leading to higher quality products and reduced waste.

Enhancing Mold Longevity through Effective Maintenance Strategies

Effective maintenance strategies play a crucial role in enhancing the longevity of plastic injection molds. One of the primary components of these strategies is regular inspection. By routinely checking for wear and tear, manufacturers can identify potential issues before they escalate into major problems. This proactive approach not only extends the mold's lifespan but also ensures consistent product quality. Additionally, attention should be given to lubrication and cleaning processes. Proper lubrication reduces friction and wear on moving parts, while thorough cleaning prevents the buildup of residues that could affect mold performance.

Effective maintenance strategies play a crucial role in enhancing the longevity of plastic injection molds. One of the primary components of these strategies is regular inspection. By routinely checking for wear and tear, manufacturers can identify potential issues before they escalate into major problems. This proactive approach not only extends the mold's lifespan but also ensures consistent product quality. Additionally, attention should be given to lubrication and cleaning processes. Proper lubrication reduces friction and wear on moving parts, while thorough cleaning prevents the buildup of residues that could affect mold performance.

Temperature control is another vital factor in mold maintenance. Molds operating under inappropriate temperature conditions can suffer from warping or other deformities, negatively impacting their effectiveness. Implementing temperature monitoring systems can help maintain optimal conditions throughout the molding process. Furthermore, training personnel on best practices for handling and maintaining molds can create a culture of care that further enhances mold longevity. By prioritizing maintenance strategies, manufacturers can achieve significant cost savings and improve production efficiency, ultimately leading to a more successful injection molding operation.