Digital Best Practices for Plastic Injection Molding?

In the realm of manufacturing, plastic injection has emerged as a crucial technique. This process involves injecting molten plastic into molds to create various products. With advancements in technology, digital best practices are reshaping how businesses approach plastic injection. Companies strive for efficiency and quality in their operations.

However, not all practices yield the expected results. Many factories still rely on outdated methods, leading to inconsistencies and waste. A focus on digital tools can bridge this gap, yet implementation is often flawed. Data-driven decisions can enhance production, but it requires commitment and proper training.

The journey towards optimized plastic injection practices is ongoing. Companies may encounter challenges along the way. Recognizing the need for continuous improvement is vital. In this evolving landscape, staying updated with digital best practices is not merely beneficial—it's essential for survival.

Understanding Plastic Injection Molding: A Digital Transformation Overview

Plastic injection molding is a crucial method in the manufacturing industry, but it requires a digital transformation to optimize processes. According to a 2021 report by MarketWatch, the global plastic injection molding market is projected to reach $300 billion by 2025. This growth indicates a significant opportunity for companies willing to modernize their operations. Digital tools can enhance design accuracy and reduce production time. Yet, many companies struggle to implement these technologies effectively.

Integrating advanced software can streamline the entire production process. Real-time data analytics can help identify inefficiencies. A study by Deloitte shows that manufacturers that adopt digital practices see up to a 20% increase in productivity. However, the digital shift isn’t without challenges. Legacy systems often resist change, leading to gaps in data integration. Moreover, staff training remains a hurdle as new technologies can intimidate the workforce.

Additionally, the use of simulation software can reduce waste and improve material usage. According to a 2022 report from the American Society of Mechanical Engineers, companies that utilize simulation experiences a 30% reduction in material costs. However, success requires a cultural shift within organizations. Without proper buy-in from all levels, even the best tools may not yield the desired results.

Digital Best Practices in Plastic Injection Molding

This chart displays key performance metrics for digital best practices in plastic injection molding. The metrics focus on process efficiency, cost reduction, lead time improvement, quality control, and customer satisfaction, reflecting the impact of digital transformation in the industry.

Key Digital Technologies Enhancing Plastic Injection Molding Processes

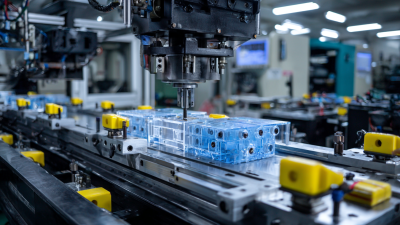

Digital technologies are transforming plastic injection molding in significant ways. One notable advance is the use of

IoT devices. These sensors monitor machines in real time. They track

temperature, pressure, and

cycle times. This data helps identify issues before they become major problems.

Tips: Regularly update software firmware. It ensures compatibility

with the latest IoT devices. This can minimize downtime and prevent costly errors.

Another key technology is simulation software. It allows engineers to

create virtual prototypes. This helps in assessing design feasibility before physical production begins. Adjustments made early can save time and material costs. However,

over-reliance on simulations can lead to overlooking real-world challenges.

Tips: Validate simulations with physical tests. Don’t skip this

step. Real-world conditions can differ from predicted outcomes.

Lastly, digital twins are becoming essential in this field. They

replicate physical assets in a digital format. This enables continuous monitoring and optimization. Yet, creating an

accurate digital twin can be complex. Inaccuracies can lead to misleading data and decisions.

Tips: Regularly cross-check your digital twin with physical

data. This helps maintain accuracy in monitoring and predictions.

Best Practices for Optimizing Design in Injection Molding

In injection molding, optimizing design is crucial for successful production. Research shows that 70% of manufacturing issues stem from design flaws. Early design verification can save time and costs. Creating a robust model promotes efficiency throughout manufacturing.

Tip: Simplify complex geometries. Reducing intricate details can enhance mold durability and ease production. Simple designs can decrease cycle time by up to 30%.

It's essential to understand material behavior during the design phase. Choosing the right resin can affect the final product. For instance, slight variations in temperature can lead to defects. Monitoring these factors minimizes waste and improves precision.

Tip: Utilize simulation tools. These can identify potential defects before physical production. Simulation helps in refining the design process, potentially cutting down time by 20%.

Implementing Automation and Data Analytics in Molding Operations

Implementing automation in plastic injection molding can significantly enhance efficiency. Machines equipped with advanced sensors gather data throughout the production process. This data helps identify trends and potential issues early. However, not every automated system offers optimal results. Misalignment between equipment and software can lead to missed opportunities. It is crucial to choose the right technology that fits your specific needs.

Data analytics plays a vital role in molding operations. Analyzing production data reveals insights into cycle times, material usage, and energy consumption. These insights can lead to adjustments that improve output. Yet, interpreting data isn’t always straightforward. There might be discrepancies or gaps in data collection. These issues can skew results and impact decision-making. Continuous training and evaluation of data analytics processes are necessary.

Challenges remain in implementing both automation and analytics. Employee resistance to new technologies can create obstacles. Additionally, outdated infrastructure may complicate integrations. Regularly assessing these factors can help streamline operations. It’s essential to maintain flexibility during this transition. Adapting strategies based on feedback will make the process smoother. Balancing automation and human oversight will ultimately drive success.

Digital Best Practices for Plastic Injection Molding

| Practice | Description | Benefits | Implementation Status |

|---|---|---|---|

| Automation of Production | Integrating robotic arms and automated systems for handling and assembly. | Increased efficiency, reduced labor costs, and improved consistency. | In Progress |

| Data Analytics | Using software to collect and analyze production data for better decision making. | Enhanced process optimization, predictive maintenance, and reduced downtime. | Implemented |

| Quality Control Systems | Real-time monitoring of product quality with machine vision systems. | Early detection of defects, lower scrap rates, and consistent product quality. | Planned |

| Supply Chain Integration | Linking suppliers and logistics data for improved material flow. | Reduced lead times and improved inventory management. | In Progress |

| Utilization of IoT Devices | Installing sensors on machinery for real-time data collection. | Improved operational visibility and data-driven decision-making. | Implemented |

Sustainability Practices in Digital Plastic Injection Molding

In the realm of digital plastic injection molding, sustainability stands out as a crucial focus. The industry must consider its environmental impact. Using recycled materials is a practical step. This reduces waste and conserves resources. It’s not just about profit; it’s about responsibility.

Digital technologies can also optimize production. Advanced simulations help identify potential waste areas. However, many companies still overlook this. They stick to old methods, missing opportunities for improvement. Adjusting designs for efficiency can further enhance sustainability efforts. This requires an open mindset and a willingness to adapt.

Water usage in cooling processes is another concern. Innovative cooling systems can lower water consumption. Yet, the adoption rate is slow. Manufacturers must rethink their cooling strategies. Implementing such changes could be challenging, but the benefits are significant. Long-term sustainability in this field requires constant evaluation and commitment to better practices.

Related Posts

-

Understanding the Science Behind Plastic Injection Molding for Innovative Manufacturing Solutions

-

How to Navigate Import and Export Certifications for Best Mold Plastic Injection Products

-

2025 How to Choose the Best Plastic Injection Tooling for Your Production Needs

-

Understanding Best Plastic Manufacturing Standards and Five Key Reasons for Global Buyers

-

Ultimate Guide to Identifying Top Quality Suppliers in Plastic Manufacturing

-

Exploring Innovative Applications of Thermoplastic Injection Molding in Modern Manufacturing