5 Essential Tips for Optimizing Your Metal Injection Molding Process

In the ever-evolving landscape of manufacturing, metal injection molding (MIM) has emerged as a pivotal technology, enabling the production of complex metal parts with exceptional precision and efficiency. According to a report by MarketsandMarkets, the global metal injection molding market is projected to reach $3.1 billion by 2025, growing at a CAGR of 10.3% from 2020. As industries seek cost-effective solutions without compromising quality, optimizing the MIM process becomes essential for enhancing productivity and profitability. By leveraging the latest advancements in materials, techniques, and technologies, manufacturers can significantly reduce lead times and manufacturing costs, ultimately delivering superior products to their clients. This blog outlines five essential tips for optimizing your metal injection molding process, ensuring you stay competitive in a challenging market.

Key Factors Influencing Metal Injection Molding Cycle Time Optimization

Optimizing the cycle time of metal injection molding (MIM) is crucial for enhancing productivity and reducing production costs. Several key factors play a significant role in achieving this optimization. One important aspect is the powder characteristics, which can significantly affect the flowability and packing density of the metal feedstock. According to a report by the Metal Powder Industries Federation, optimizing powder particle size can lead to a reduction in cycle time by as much as 20% due to improved mold filling and reduced bottlenecks during the injection phase.

Another critical factor is the temperature control during the injection and sintering processes. Maintaining the appropriate temperatures is essential for preventing defects such as warping and ensuring uniform density throughout the part. A study published in the Journal of Materials Processing Technology indicates that controlling the heating rate can minimize cycle times; for instance, a precise control of the sintering temperature can decrease cycle time by an additional 15-30%.

Lastly, the design of the mold itself can greatly influence cycle times. Utilizing advanced mold designs and materials with better thermal properties can lead to faster cooling and heating times. Industry research has shown that implementing conformal cooling channels can reduce cooling times by 40%, significantly impacting overall cycle efficiency. By focusing on these key factors, manufacturers can optimize their MIM processes and gain a competitive edge in the market.

Understanding the Impact of Material Selection on Part Strength and Quality

Material selection plays a pivotal role in the metal injection molding (MIM) process, significantly influencing the strength and quality of the final parts. According to a report by the Metal Powder Industries Federation, the mechanical properties of MIM components can vary widely based on the materials used, with some alloys demonstrating up to 30% greater tensile strength compared to standard alternatives. Choosing the right metal powder not only affects the performance characteristics but also the overall production efficiency of the MIM process.

To optimize your MIM process, consider starting with a comprehensive materials analysis. Select powders that align with the intended application, ensuring they meet specific strength and corrosion resistance requirements. Additionally, ensure compatibility with your injection molding equipment, as some materials may necessitate adjustments in processing conditions.

Moreover, prioritize quality control through rigorous testing of both raw materials and finished products. Implementing stringent quality checks can lead to a reduction in waste and rework costs. Monitoring powder size distribution and flowability can also enhance consistency in molding, reducing defects in the final output. By integrating these tips into your material selection strategy, you can significantly elevate the performance and reliability of your MIM components.

5 Essential Tips for Optimizing Your Metal Injection Molding Process

| Tip | Description | Material Selection Impact | Part Strength Rating (1-10) | Quality Rating (1-10) |

|---|---|---|---|---|

| 1. Choose the Right Feedstock | Selecting the appropriate feedstock will improve sintering outcomes and part performance. | High-quality feedstock ensures better part density. | 9 | 8 |

| 2. Optimize Injection Parameters | Fine-tuning injection speed, pressure, and temperature can reduce defects. | Improved flow increases part uniformity. | 8 | 7 |

| 3. Ensure Proper Design Features | Design for manufacturability to enhance strength. | Effective design minimizes stress concentrations. | 10 | 9 |

| 4. Maintain Equipment Regularly | Routine maintenance prevents wear and tear that can affect quality. | Consistent equipment operation improves part quality. | 7 | 8 |

| 5. Evaluate Post-Sintering Treatments | Utilize heat treatment methods to improve mechanical properties. | Post-treatment enhances strength and durability. | 9 | 9 |

Best Practices for Reducing Defects in Metal Injection Molding Processes

Metal injection molding (MIM) is a complex process that can yield high-quality metal parts when executed properly. However, minimizing defects is crucial for ensuring efficiency and product integrity. One of the first steps to reducing defects is optimizing the feedstock formulation. The right balance of metal powder and binder ensures proper flowability and consistency, leading to fewer inconsistencies during the injection process. Conducting thorough material tests and adjustments based on specific application requirements can significantly enhance the overall quality.

Additionally, maintaining precise control over processing parameters like temperature, pressure, and injection speed plays a vital role in defect reduction. Variations in any of these factors can result in issues like warping or incomplete filling. Implementing real-time monitoring systems allows operators to react swiftly to any deviations, ensuring that the process remains within the desired specifications. Regular maintenance of machinery also cannot be overstated, as wear and tear can lead to unpredictable results that compromise product quality. By focusing on these best practices, manufacturers can effectively reduce defects and enhance productivity in their metal injection molding processes.

Effective Tool Design Strategies to Enhance MIM Efficiency and Precision

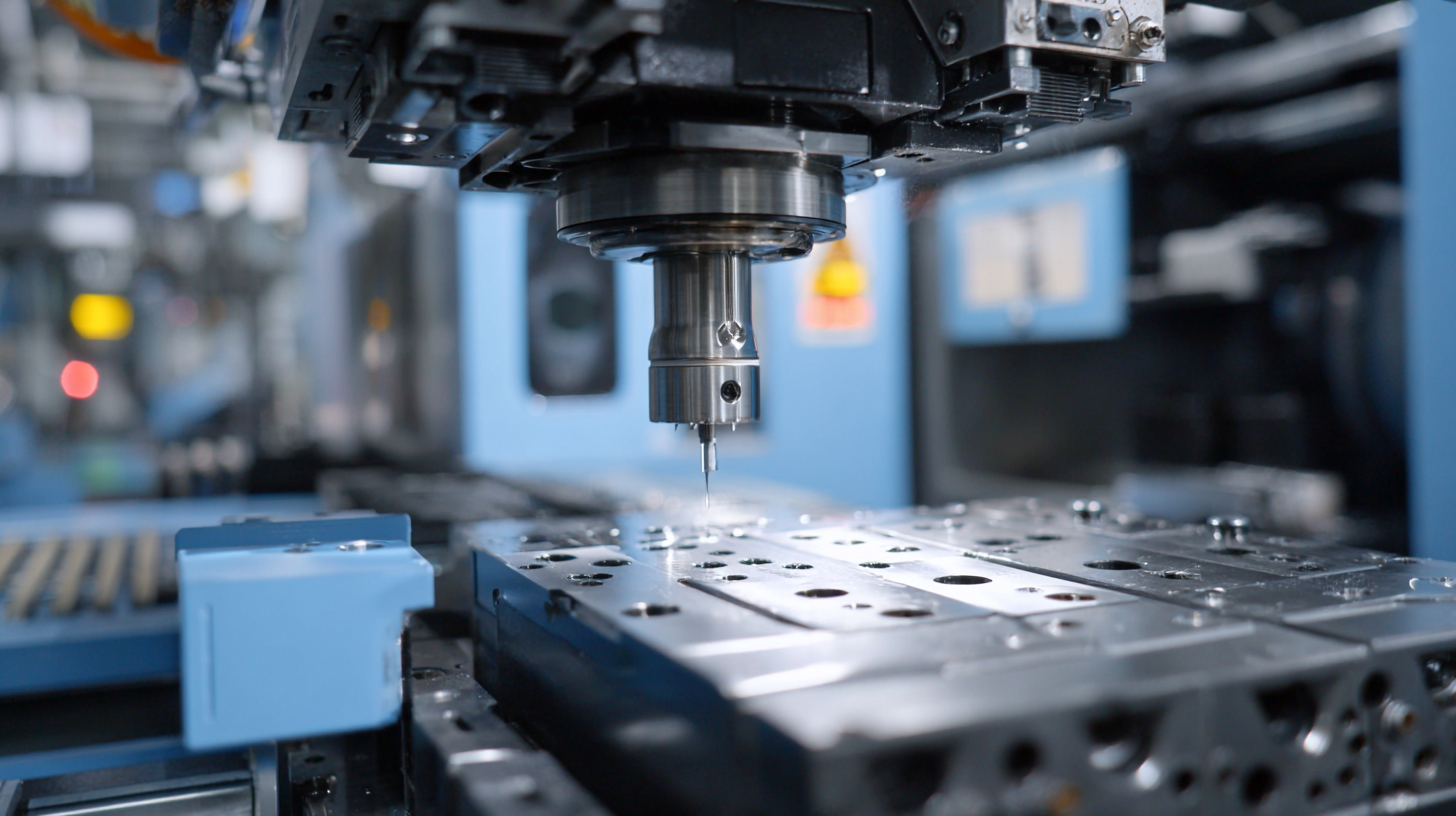

Tool design plays a pivotal role in enhancing the efficiency and precision of the Metal Injection Molding (MIM) process. One of the essential strategies is to ensure that the tooling is optimized for the specific material being used. Different metals require varying temperatures and flow characteristics, so designing molds that accommodate these variables can significantly reduce cycle times and improve the overall quality of the molded parts. Utilizing simulation software during the design phase can also help in predicting potential issues, allowing for adjustments before actual production begins.

Another key design consideration is the incorporation of efficient cooling channels within the mold. The temperature management of the tooling directly affects the uniformity of the final product and the speed of the cycle. By strategically placing cooling channels to minimize thermal gradients, manufacturers can ensure consistent cooling, which leads to reduced warping and enhanced dimensional accuracy. Furthermore, utilizing modular tool designs can facilitate easier maintenance and faster adjustments, allowing manufacturers to respond swiftly to changing production needs without compromising quality.

Utilizing Industry 4.0 Technologies for Real-time Monitoring and Optimization

In the age of Industry 4.0, optimizing your metal injection molding process is crucial for maintaining competitive advantage in manufacturing. Embracing advanced technologies like IoT sensors and real-time monitoring systems can significantly enhance efficiency and productivity. By leveraging these tools, facilities can achieve seamless integration across machines and processes, allowing for data-driven decisions that optimize production in real time.

One essential tip for optimization is to invest in industrial robots and automation systems. These technologies not only reduce manual labor costs but also increase consistency and precision in production. Another key strategy involves the implementation of advanced monitoring systems that utilize machine vision and predictive analytics to identify issues before they escalate. This proactive approach can minimize downtime and ensure smoother operations.

Moreover, developing a robust digital twin of your manufacturing system can provide valuable insights into process simulations and performance predictions. By analyzing data collected from various processes, manufacturers can optimize workflows, reduce waste, and enhance overall productivity, leading to substantial growth in the increasingly competitive market.

Related Posts

-

5 Expert Tips for Optimizing Your Metal Injection Mold Design

-

Innovative Examples of Automotive Injection Molding Applications in the Industry

-

Essential Checklist for Effective Mold Design in Injection Molding Processes

-

How to Identify Top Suppliers for Optimal Injection Molding Mold Design

-

How to Choose the Best US Injection Molding Solutions for Your Manufacturing Needs

-

Exploring the Role of Import and Export Certifications in Best Mold Manufacturing