Leveraging Excellent After Sales Support for Cost Effective Future of Best Mold Design in Injection Molding

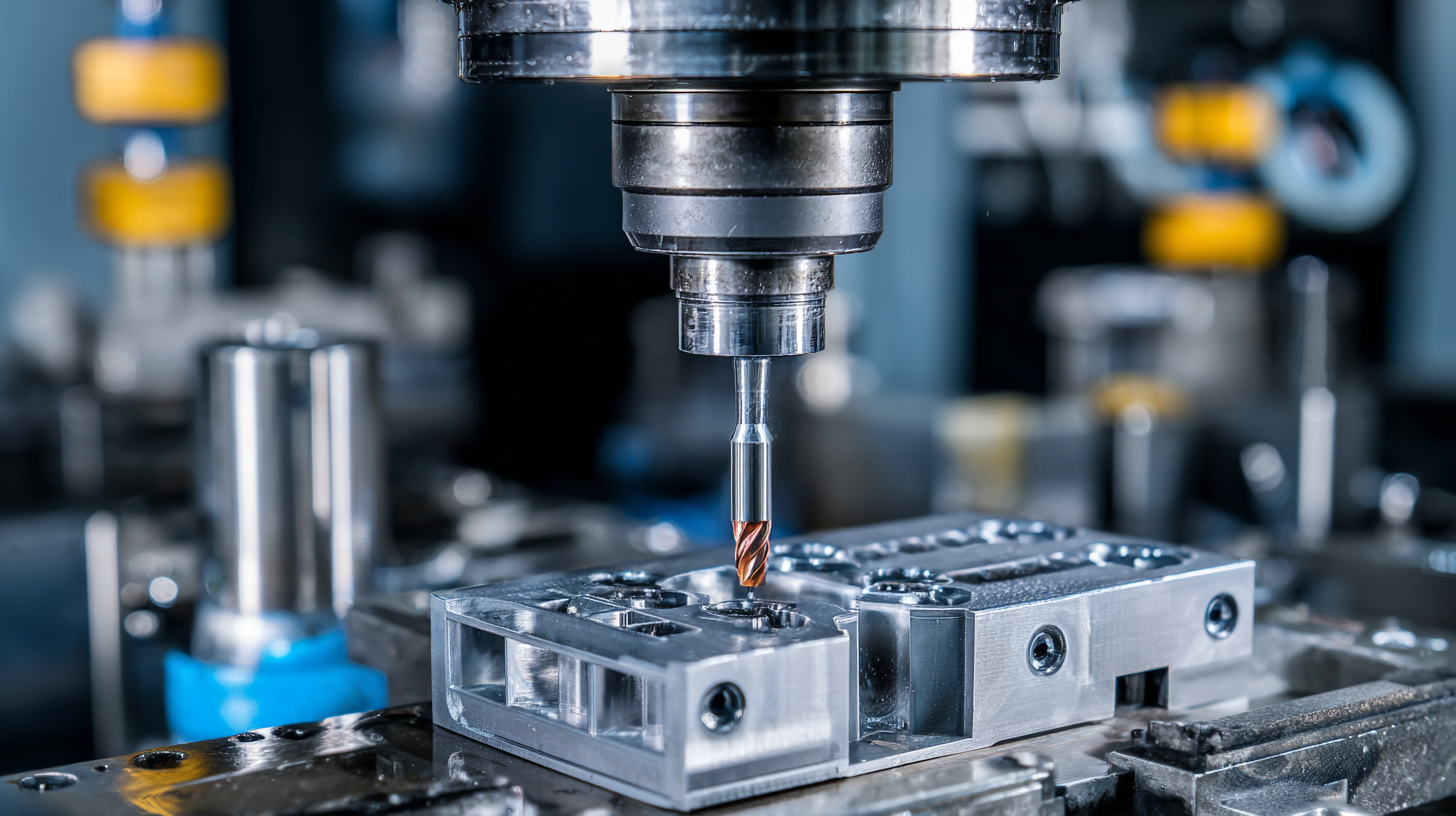

The injection molding industry is set to experience significant growth by 2025, with market reports indicating an anticipated compound annual growth rate (CAGR) of over 5% from 2020 to 2025. This surge is closely linked to advancements in mold design for injection molding, which plays a crucial role in optimizing production efficiency and reducing costs. As manufacturers increasingly recognize the importance of excellent after-sales support, the relationship between support services and innovative mold design becomes vital. Research suggests that companies leveraging robust after-sales support can achieve up to 30% higher efficiency and reduced rework costs, underpinning the critical intersection of customer service and cutting-edge design. This blog will explore how effective after-sales strategies can foster a cost-effective future in mold design for injection molding.

The Importance of After Sales Support in Injection Molding Efficiency

A crucial component in enhancing the efficiency of injection molding lies in the effectiveness of after sales support. According to a report by Global Market Insights, the injection molding market is projected to exceed $300 billion by 2025, driven in part by advancements in after sales services. Companies that prioritize robust after sales support can reduce downtimes and improve overall productivity. Research shows that enterprises with strong after sales teams can achieve a 25% increase in customer satisfaction rates, leading to repeat business and reduced costs associated with mold repair or replacement.

Moreover, effective after sales support contributes significantly to the longevity of mold designs. Data from the American Society of Mechanical Engineers indicates that molds maintained through proactive service can last up to 30% longer than those left unmanaged. This not only translates to lower capital expenditures but also reduces waste, promoting a more sustainable injection molding process. By investing in excellent after sales support, manufacturers are ensuring that their best mold designs remain efficient and cost-effective in a competitive market.

Leveraging Excellent After Sales Support for Cost Effective Future of Best Mold Design in Injection Molding

| Dimension | Description | Impact on Efficiency | Cost Effectiveness |

|---|---|---|---|

| Technical Support | Assistance for resolving issues post-sale. | Reduces downtime significantly. | Minimizes repair costs. |

| Training Programs | Training for staff on equipment usage. | Enhances productivity and reduces errors. | Lower rework costs. |

| Maintenance Services | Scheduled and emergency maintenance. | Increases machine lifespan. | Reduces total cost of ownership. |

| Feedback Mechanism | System to capture and utilize customer feedback. | Improves product design and service. | Enhances customer retention. |

| Spare Parts Availability | Ready access to replacement components. | Minimizes production delays. | Lower inventory costs when managed effectively. |

Key Metrics: Cost Reduction Through Effective Mold Design Support

In the realm of injection molding, effective mold design support plays a pivotal role in cost reduction. One key metric to consider is the efficiency of after-sales support. When customers receive timely assistance and expert guidance post-purchase, it leads to reduced downtime and optimized production processes. This support can manifest in various forms, including troubleshooting mold issues, providing maintenance tips, and evolving design enhancements based on client feedback. By proactively addressing potential challenges, companies not only save costs but also strengthen their partnerships with clients.

Furthermore, integrating advanced technology into mold design support can greatly streamline operations. Utilizing simulation software and predictive maintenance tools allows for precise adjustments that enhance mold performance and longevity. This capability not only minimizes material waste but also shortens lead times, which is crucial in today’s fast-paced manufacturing environment. By prioritizing these aspects, businesses can leverage excellent after-sales support as a strategic advantage, ultimately achieving a more cost-effective future in mold design within the injection molding industry.

Case Studies: Successful After Sales Strategies in the Molding Industry

In the molding industry, successful after-sales strategies are pivotal for ensuring customer satisfaction and establishing long-term partnerships. One notable case study involves a leading mold manufacturing company that implemented a robust support system post-delivery. By providing comprehensive training and quick response assistance to their clients, they not only enhanced the functionality of their molds but also increased customer loyalty. This proactive approach allowed them to identify and resolve issues swiftly, setting a standard for their competitors.

Tips for effective after-sales support include developing tailored service packages that cater to specific client needs. Regular follow-ups can help gather feedback, which is essential for continuous improvement. Additionally, investing in technology for remote assistance can drastically reduce downtime, allowing clients to return to production faster.

Another case study showcases a company that utilized customer relationship management (CRM) tools to track customer interactions and preferences. By analyzing this data, they could offer personalized recommendations and timely upgrades. This not only improved user experience but also facilitated proactive maintenance, ensuring that clients' molds operated at peak efficiency. Emphasizing the importance of customer-centric practices can lead to impressive gains in both reputation and profitability in the injection molding sector.

Integrating Customer Feedback for Continuous Improvement in Mold Design

In the competitive world of injection molding, integrating customer feedback is essential for continuous improvement in mold design. By actively seeking and incorporating insights from clients, manufacturers can enhance the functionality and efficiency of their molds, ensuring that the final products meet market demands. This feedback loop not only highlights areas needing innovation but also fosters a collaborative relationship between designers and users, promoting a culture of excellence in both design and production.

Furthermore, leveraging excellent after-sales support plays a pivotal role in gathering valuable customer insights. When companies offer robust support, it encourages clients to share their experiences and suggestions for improvements. Engaging in thorough post-delivery assessments allows manufacturers to identify recurring issues and anticipate future needs, paving the way for cost-effective solutions. By aligning their mold design processes with real-world application feedback, businesses can create more durable, efficient, and user-friendly products, ultimately ensuring long-term success in the injection molding industry.

Future Trends: How After Sales Support Shapes the Injection Molding Landscape

The injection molding landscape is undergoing significant transformation, driven in part by the emphasis on after-sales support. As companies face increasing pressure to improve efficiency and product quality, robust after-sales support has emerged as a key differentiator. Recent insights from the Chinese hot runner industry indicate that government policies are actively guiding advancements in mold technology, providing vital backing for businesses in this sector. This strategic direction not only boosts competitiveness but also enhances customer satisfaction through efficient problem resolution and product optimization.

**Tip:** Invest in comprehensive after-sales support teams to leverage customer feedback for continuous improvement. Engaging with clients post-purchase allows for better understanding of their needs, facilitating tailored updates and innovations.

Polymer jetting technology continues to show promise within the 3D printing market, suggesting that companies should also consider integrating advanced techniques alongside their traditional molding processes. Reports indicate a compound annual growth rate in the metal and ceramic injection molding market, signaling an increasing demand for innovative solutions.

**Tip:** Stay informed about emerging technologies and industry trends to anticipate shifts in market demand and position your company as a leader in adopting new practices. Prioritizing research and development will ensure that your injection molding processes remain at the forefront of the industry.