Top 10 Injection Molding Tolerances Tips You Need to Know for Perfect Parts

Injection molding tolerances are critical factors that define the quality and precision of parts produced through this widely utilized manufacturing process. According to a report by the Society of Plastics Engineers, maintaining proper tolerances can significantly enhance product performance and reduce waste—key metrics in today's competitive market. In fact, up to 40% of production costs can be attributed to inefficiencies during the injection molding process, where even slight deviations from specified tolerances can lead to increased defects and customer dissatisfaction.

As manufacturers strive for excellence, understanding the intricacies of injection molding tolerances becomes essential. Industry studies indicate that a mere 0.1 mm variation can influence assembly, functionality, and overall product longevity. Moreover, stricter tolerance ranges necessitate advanced tooling and meticulous attention to detail, all while keeping an eye on cost efficiency. This makes it paramount for engineers and manufacturers alike to familiarize themselves with essential tips and best practices to achieve perfect parts, thereby enhancing operational efficiency and customer satisfaction. By mastering the fundamentals of injection molding tolerances, businesses can not only ensure high-quality output but also maintain a competitive edge in an increasingly demanding marketplace.

Understanding Injection Molding Tolerances: A Key to Precision Parts

Understanding injection molding tolerances is crucial for achieving precision parts in manufacturing. Injection molding is a complex process that involves transforming raw materials into finished products, and the tolerances set during this process determine the allowable variations in the dimensions of these parts. These tolerances ensure that the components fit together as intended, maintaining functionality and aesthetic quality. A deep grasp of these parameters not only enhances the manufacturability of designs but also helps in minimizing waste, reducing costs, and improving overall product performance.

Setting the right tolerances is a balance between engineering feasibility and manufacturing capability. Precision in tolerances plays a vital role in industries such as automotive, medical, and consumer goods, where even minor variations can lead to significant impacts on product safety and usability. Engineers must consider factors like material behavior, cooling rates, and equipment capabilities when defining these tolerances. By enhancing their understanding of injection molding tolerances, professionals can better design parts that meet strict specifications, ensuring reliability and consistency in production processes.

Top 10 Injection Molding Tolerances Tips You Need to Know for Perfect Parts

| Tolerance Type | Typical Value | Factors Affecting Tolerance | Tips for Improvement |

|---|---|---|---|

| Dimensional Tolerance | ±0.1 mm | Material shrinkage, cooling rate | Optimize cooling process |

| Geometric Tolerance | ±0.05 mm | Machine calibration | Regular calibration checks |

| Surface Finish Tolerance | Ra 1.6 μm | Mold design, material | Use polishing techniques |

| Position Tolerance | ±0.05 mm | Part alignment, tooling wear | Ensure proper alignment |

| Orientation Tolerance | ±0.1 mm | Injection direction | Analyze flow direction |

| Draft Angle Tolerance | 1-3 degrees | Material type | Adjust mold design |

| Flatness Tolerance | ±0.1 mm | Mold setup | Improve mold plate surface |

| Roundness Tolerance | ±0.05 mm | Tooling conditions | Refine machining process |

| Concentricity Tolerance | ±0.03 mm | Part placement | Use fixtures |

| Symmetry Tolerance | ±0.05 mm | Mold design | Review design symmetry |

Factors Affecting Tolerances in Injection Molding Processes

Injection molding is a widely utilized manufacturing process known for producing intricate shapes and components with high precision. However, achieving optimal tolerances is critical, as numerous factors can influence the end results. A key factor is the material selection; different polymers exhibit varying shrink rates, which can significantly impact the final dimensions of the molded parts. According to the Society of Plastics Engineers (SPE), the shrinkage rate can range from 0.2% to 2.0%, depending on the material, and an accurate understanding of these values can help engineers predict the necessary adjustments in mold design.

Another critical factor affecting tolerances is the processing conditions, such as temperature and pressure. For instance, maintaining a consistent melt temperature can minimize variations in part dimensions. A study published in the Journal of Manufacturing Science and Engineering highlights that a 10°C increase in melt temperature can lead to a 0.3% decrease in shrinkage. Moreover, injection speed and cooling rates must be optimized to achieve the desired level of precision. Variability in these parameters may lead to defects such as warpage or poor surface finish, which can ultimately compromise the part's functionality. Understanding and controlling these factors are essential for achieving tighter tolerances and manufacturing perfect components in injection molding processes.

Essential Tips for Achieving Optimal Injection Molding Tolerances

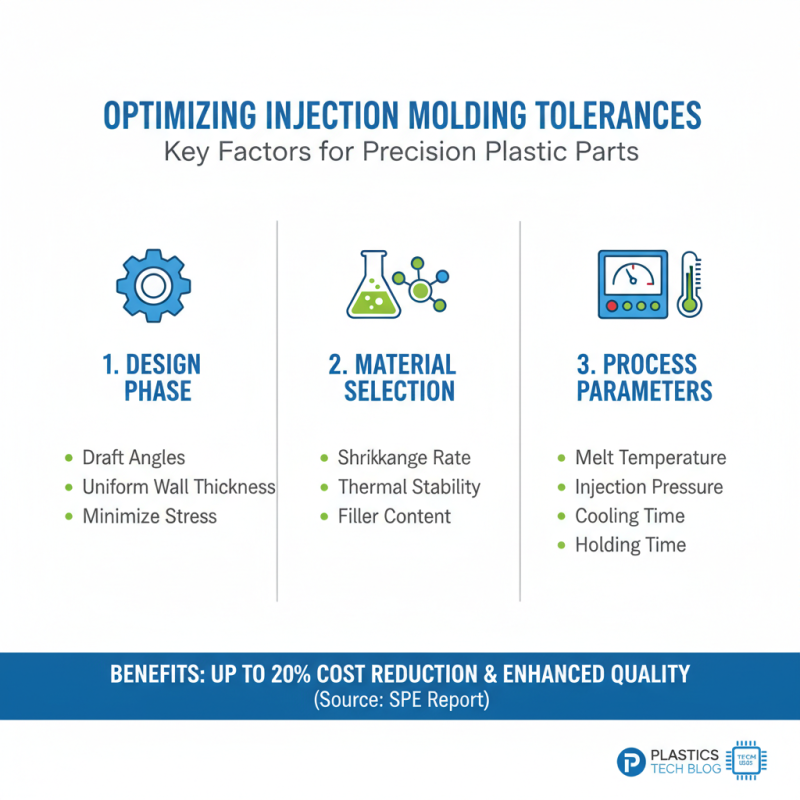

Achieving optimal tolerances in injection molding is crucial for the functionality and performance of plastic parts. The precision required often hinges on a combination of factors, including design, material selection, and process parameters. According to a report by the Society of Plastics Engineers, managing tolerances effectively can reduce production costs by as much as 20% while simultaneously enhancing product quality. To optimize injection molding tolerances, it’s essential to consider the design phase meticulously. Utilizing techniques such as draft angles and proper wall thickness can significantly minimize stress concentrations and warping in finished parts.

Material properties play a vital role in achieving desired tolerances as well. Thermoplastics, such as ABS and polycarbonate, exhibit different shrinkage rates during cooling, which directly impacts dimensional accuracy. The American Society for Testing and Materials outlines that maintaining a consistent processing temperature and injection speed helps to mitigate variations in dimensions. Implementing precise control measures will result in improved repeatability in production runs and ultimately yield parts that meet stringent specifications. By focusing on both design considerations and material characteristics, manufacturers can ensure that they achieve the ideal tolerances necessary for their injection-molded products.

Common Tolerance Issues and How to Resolve Them in Production

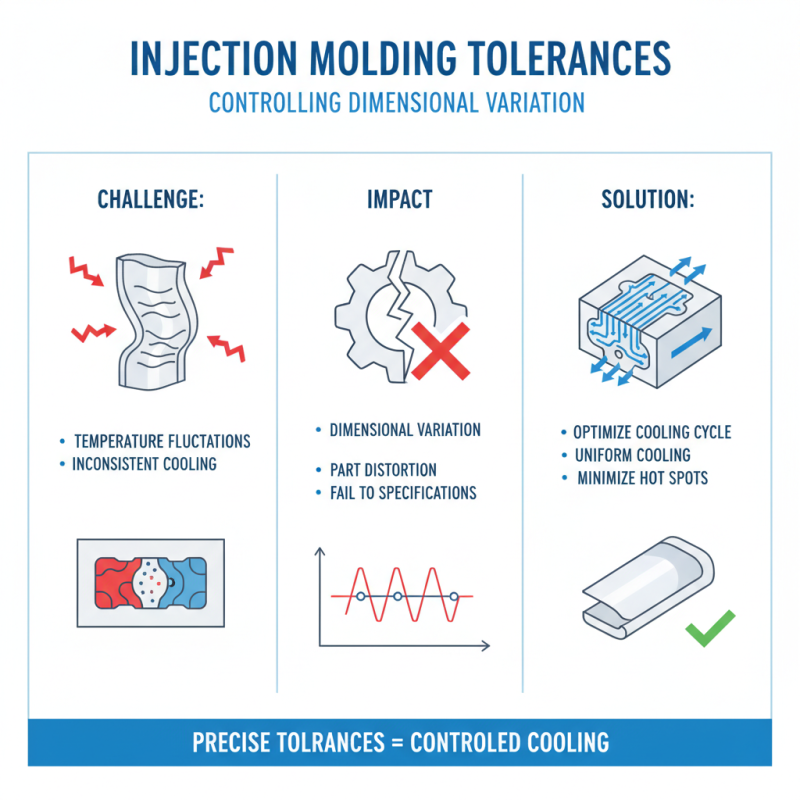

Achieving precise tolerances in injection molding can be challenging, and common issues often arise during production. One frequent problem is dimensional variation caused by fluctuations in temperature. When the plastic material cools too quickly or inconsistently, it may become distorted, resulting in parts that do not meet specifications. To resolve this, manufacturers should carefully control the cooling cycle within the mold design, ensuring uniform cooling and minimizing hot spots that can lead to defects.

Another common issue is the warping of parts due to internal stresses during the molding process. This can occur if the material is injected too quickly or if the part design lacks adequate support structures. To mitigate warping, it is essential to optimize the part design for material flow and to adjust injection speed and pressure accordingly. Additionally, employing proper mold design features such as ribs or gussets can help distribute stress evenly, supporting the structural integrity of the final product and maintaining tight tolerances.

Best Practices for Measuring and Inspecting Tolerances in Molding Parts

Measuring and inspecting tolerances in molding parts is crucial for achieving high-quality products. One of the best practices is to use calibrated measuring tools that are suitable for the specific dimension requirements. Tools like digital calipers and micrometers offer precision and help in obtaining accurate measurements. Always ensure that your measurement tools are regularly calibrated to avoid discrepancies that could affect the final output.

Another important aspect is establishing a clear tolerance standard before starting the molding process. Communicating these standards with your team ensures everyone is aligned on expectations and reduces the risk of errors during production. It's also beneficial to incorporate a systematic approach toward sampling and testing molded parts. Implementing regular inspections at various stages of production can help catch deviations early, thus minimizing waste and enhancing efficiency.

Additionally, utilizing software that assists in modeling and simulating the injection process can provide insights into how materials behave under specific conditions. This insight allows engineers to make informed decisions on adjustments to the design or process, ensuring that tolerances are met effectively. By following these tips, you can maintain the integrity of your molds and achieve the perfect balance between functionality and precision.

Related Posts

-

Top 10 Benefits of the Injection Moulding Process You Need to Know

-

Exploring the Role of Import and Export Certifications in Best Mold Manufacturing

-

Leveraging Excellent After Sales Support for Cost Effective Future of Best Mold Design in Injection Molding

-

Innovative Examples of Automotive Injection Molding Applications in the Industry

-

In Depth Comparison of Plastic Injection Mold Tooling Techniques and Their Industry Impact

-

What is the Impact of Medical Injection Molding on Healthcare Innovation and Patient Outcomes