How to Master Plastic Injection Molding for Effective Manufacturing Processes

In the rapidly evolving landscape of manufacturing, mastering plastic injection molding has become an essential skill for professionals aiming to optimize production efficiency and product quality. According to Dr. Emily Choi, a renowned expert in the field of plastic injection molding, "The key to successful manufacturing lies in understanding not just the process, but the materials and design intricacies involved." This underscores the importance of a comprehensive approach to injection molding, where every element—from design to execution—plays a crucial role in achieving desirable outcomes.

As industries demand higher precision and sustainability, the ability to effectively harness the benefits of plastic injection molding can set a company apart in a competitive market. By focusing on advancements in technology, material science, and process optimization, manufacturers can reduce waste, enhance durability, and improve production timelines. Dr. Choi emphasizes that "Innovation in injection molding technology is driving the future of manufacturing," highlighting the need for practitioners to stay informed and adaptable in their methodologies.

In this guide, we will explore the fundamental principles of plastic injection molding, along with best practices for mastering its complexities. Whether you are a seasoned professional or a newcomer seeking to enhance your skills, understanding the nuances of this vital manufacturing process is imperative for success in today's economy.

Understanding the Fundamentals of Plastic Injection Molding Technology

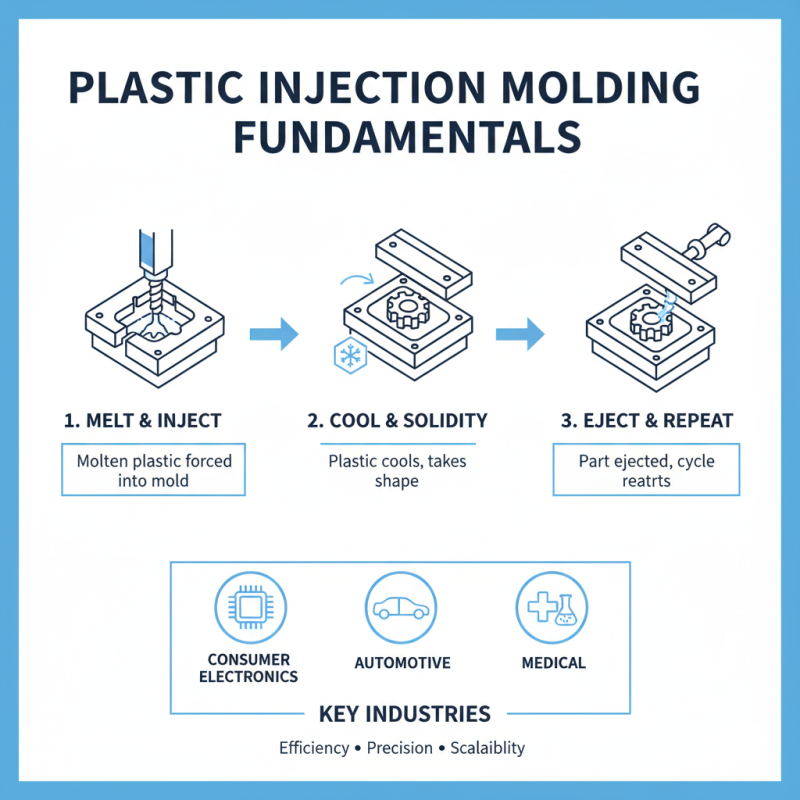

Understanding the fundamentals of plastic injection molding technology is crucial for effective manufacturing processes. Plastic injection molding is a highly efficient method for producing complex and precise plastic parts, widely utilized in industries such as consumer electronics, automotive, and medical. The process involves injecting molten plastic into a mold, where it cools and solidifies to form the desired shape. Advances in technology have led to the development of various techniques that enhance the precision, efficiency, and scalability of injection molding, catering to the growing demand for high-quality plastic components.

The plastic contract manufacturing market is experiencing significant growth, driven by the increasing utilization of plastics in home appliances and other sectors. Companies are outsourcing plastic production to specialized service providers who offer a range of solutions, including injection molding, extrusion, and blow molding. As a result, the injection molded plastics market is projected to expand significantly, underscoring the importance of mastering injection molding technology for manufacturers aiming to capitalize on this upward trend. Understanding these fundamentals not only improves production efficiency but also contributes to sustainable practices in manufacturing, aligning with modern environmental awareness.

Key Parameters for Optimizing Injection Molding Processes and Outputs

To optimize injection molding processes and outputs, understanding key parameters is crucial.

The temperature of both the molten plastic and the mold plays a significant role in the final product quality.

Maintaining the appropriate melt temperature ensures proper flow and reduces the risk of defects, while the mold temperature affects solidification and dimensional stability.

Careful calibration of these temperatures can lead to enhanced cycle times and improved surface finishes.

Another critical factor is the injection speed and pressure.

A high injection speed may increase the likelihood of defects such as short shots or sink marks, while too low a speed can result in incomplete filling.

Pressure settings must be optimized to ensure that the plastic fills the mold uniformly without creating excessive stress in the material.

Monitoring these variables in real-time can significantly impact production efficiency and the mechanical properties of the molded parts.

By mastering these parameters, manufacturers can achieve higher quality outputs and reduce waste during the injection molding process.

Common Defects in Injection Molding and How to Troubleshoot Them

Injection molding is a highly efficient manufacturing process, but it is not without its challenges. Common defects can arise during production, negatively impacting the quality of the final product. One such defect is short shots, where the molten plastic does not fill the entire mold cavity. This issue can often be resolved by increasing the shot size or adjusting the mold temperature to ensure better material flow.

Another frequent problem is warping, which occurs when the molded part cools unevenly and distorts. To troubleshoot warping, manufacturers can modify the cooling time and temperature or re-evaluate the design of the mold to promote more uniform cooling. Additionally, surface blemishes such as sink marks can arise, often due to insufficient material or inconsistent cooling rates. Addressing these defects may involve increasing the material volume or optimizing the cooling process to ensure the part maintains its shape and integrity throughout the molding cycle.

By understanding and identifying these defects, manufacturers can implement effective troubleshooting strategies, enhancing the overall quality of their injection-molded products and ensuring a smoother production process.

Common Defects in Injection Molding and Their Frequencies

Advanced Techniques for Enhancing Production Efficiency in Injection Molding

In the world of plastic injection molding, enhancing production efficiency is crucial for maintaining competitiveness and profitability. One advanced technique involves implementing process optimization through the use of simulation software. By modeling the injection molding process digitally, manufacturers can identify potential bottlenecks and troubleshoot issues before actual production begins. This preemptive analysis allows for adjustments to be made in the design phase, leading to reduced cycle times and waste, ultimately increasing productivity.

Another critical approach to boosting efficiency is the adoption of automation technologies. Integrating robotic systems for tasks such as part handling and quality inspections can significantly speed up production workflows and free up human operators for more complex tasks. Additionally, employing real-time monitoring systems ensures that any deviations in the manufacturing process are quickly addressed, minimizing downtime and resource wastage. These advanced techniques not only streamline operations but also contribute to higher-quality outputs, making them essential for any manufacturer looking to master the art of injection molding.

The Role of Materials and Their Properties in Injection Molding Success

The choice of materials is crucial in the plastic injection molding process, as it directly influences the quality and performance of the final product. Different types of plastics, such as ABS, polypropylene, and polycarbonate, possess unique properties that determine their suitability for various applications. For instance, ABS is renowned for its toughness and impact resistance, making it ideal for consumer products, while polypropylene is favored for its chemical resistance and lightweight nature, suitable for packaging and automotive parts. Understanding these properties allows manufacturers to select the right material, optimizing functionality and durability.

Moreover, the processing characteristics of these materials during molding are essential for achieving desired results. Factors such as melt flow rate, viscosity, and thermal stability play significant roles in how the material behaves when injected into molds. A well-balanced selection of material properties can lead to enhanced molding accuracy and reduced defects, ultimately improving production efficiency. By mastering the interplay between material selection and molding techniques, manufacturers can ensure a robust injection molding process that meets both design specifications and market demands.

Related Posts

-

How to Choose the Best US Injection Molding Solutions for Your Manufacturing Needs

-

Why Understanding Injection Molding Tooling Can Transform Your Manufacturing Success

-

Mastering Precision Tooling Techniques for Maximum Efficiency and Quality

-

Unlocking Efficiency: How Precision Plastic Injection Molded Parts Boost Production by 30% in Manufacturing

-

How to Optimize Injection Molding Tolerances for Enhanced Product Quality and Precision

-

What is the Impact of Medical Injection Molding on Healthcare Innovation and Patient Outcomes