How to Master Plastic Injection Molding for Your Projects?

Plastic injection molding is both an art and a science. It transforms raw materials into intricate designs. As noted by industry expert John Smith, "Mastering this craft requires patience and precision." This statement highlights the complexities of the process.

In plastic injection molding, every detail matters. From temperature control to mold design, small errors can lead to significant problems. Tackling these challenges can be daunting for beginners. Many struggle with understanding the mixtures and balance needed for optimal results.

It's easy to overlook the importance of consistency in production. Yet, achieving uniformity is crucial for quality. As you embark on mastering this technique, expect a journey filled with trial and error. Each project will teach you valuable lessons and refine your skills. Embrace the imperfections and learn from them.

Understanding the Basics of Plastic Injection Molding

Plastic injection molding is a fascinating process that transforms raw plastic into usable products. Understanding its basics can greatly enhance your projects.

It starts with granules of plastic, heated until they melt. This molten plastic is then injected into a mold, where it cools and solidifies. The result is a precise, uniform object.

However, mastering this technique requires attention to detail. Each mold design affects the final product's quality. Common issues include sink marks and warping, which stem from improper cooling time or uneven material distribution.

Newcomers often overlook these factors, leading to disappointing results.

Another important aspect is material selection. Different plastics yield different results. Some may be rigid, while others are flexible. Experimenting with various types can help identify the best fit for your project.

It’s essential to embrace mistakes as learning opportunities. Reflecting on what went wrong aids in gradual improvement in the craft of injection molding.

Key Components and Equipment Used in Injection Molding

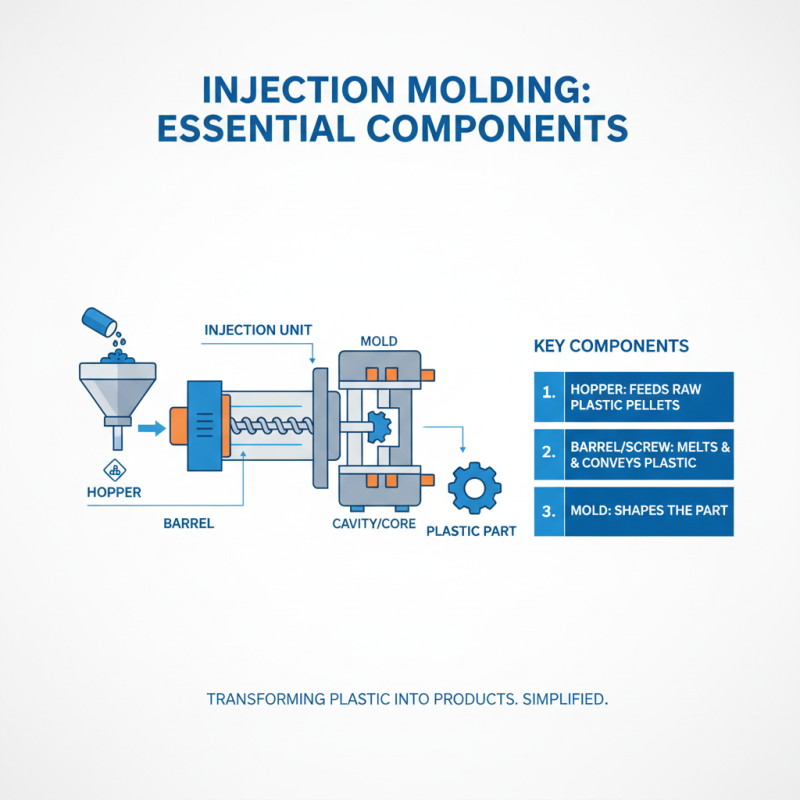

Injection molding is a key process for producing plastic parts. Understanding the essential components and equipment can help you excel in your projects. The injection molding machine is a vital piece of machinery. It consists of a hopper, barrel, and injection unit. Each component plays a role in transforming raw plastic into useful products.

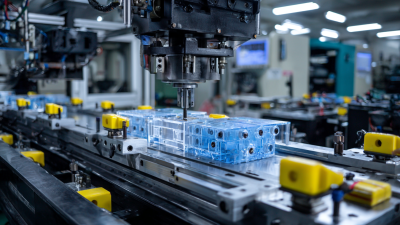

Molds are another critical aspect. A good mold dictates the final shape and quality. It’s made of durable materials to withstand high pressure. Consider the cooling system within the mold as well. Efficient temperature control affects the cycle time and the quality of the product.

Tips for success in this field: Always maintain your equipment. Regular checks can prevent breakdowns. Experiment with different molds to find the best fit for your project. Don't hesitate to make adjustments. Learning from mistakes will sharpen your skills.

Remember, precise measurements matter. Small deviations can lead to significant issues. Focus on each step of the process to ensure a high-quality output. Proper training can seem tedious, but it is essential for mastering injection molding.

Step-by-Step Process of Plastic Injection Molding

Mastering the art of plastic injection molding can seem daunting. Understanding the step-by-step process is crucial. It begins with designing your mold. Precision is key here. A well-designed mold can significantly increase production efficiency. In fact, according to industry reports, a robust mold design can enhance output by up to 30%.

Once the mold design is ready, the next step is selecting the right plastic material. The choice of material directly affects the quality and durability of the final product. Polypropylene, for instance, is popular due to its flexibility and strength. However, the improper selection can lead to defects. It’s not uncommon to encounter issues like warping or incomplete filling.

Heating and injecting the material comes next. This phase can be tricky. Maintaining the right temperature is vital for uniform melting. If the temperature is too high, it can degrade the plastic. If too low, the material may not flow properly. Monitoring these parameters requires precision. Errors at this stage often lead to a waste of both time and resources, reflecting the need for constant refinement and learning.

Plastic Injection Molding Process Mastery: Project Time Estimates

This bar chart illustrates the estimated time required for each phase of the plastic injection molding process. Understanding these time allocations can help in project planning and management.

Common Challenges and Solutions in Injection Molding

Injection molding is a powerful manufacturing process. Yet, it poses several challenges that can impact project success. One common issue is material flow. According to industry reports, improper molding temperatures can lead to incomplete parts. Ensuring the right melt temperature is essential. A report from the Society of Plastics Engineers indicates that optimizing temperatures can reduce defects by up to 30%.

Another significant challenge is cycle time. Many manufacturers underestimate the impact of cooling times on overall productivity. Research suggests that inefficient cooling can increase cycle times by as much as 50%. Investing in advanced cooling systems may help alleviate this problem. However, proper design and layout of cooling channels are equally critical to ensure effectiveness.

Dimensional accuracy is also a concern in injection molding. Variability can stem from machine calibration, environmental factors, and material properties. Reports indicate that about 20% of injection-molded parts fail quality checks due to dimensional errors. Regular inspections and adjustments can mitigate these risks. Reflecting on these challenges is crucial for continuous improvement in injection molding processes.

Tips for Optimizing Your Injection Molding Projects

Plastic injection molding is a complex process that requires precision and attention to detail. To optimize your injection molding projects, consider a few key tips. Industry reports indicate that about 80% of all plastics manufactured involve injection molding. This highlights the importance of mastering the technique.

One essential tip is to understand your material properties. Different plastics behave differently under heat and pressure. For example, thermoplastics can be re-melted while thermosets cannot. This knowledge helps in selecting the right material for each project. Conducting tests for shrinkage and flow rates can also provide crucial insights.

Another critical factor is mold design. A well-designed mold not only enhances production efficiency but also minimizes defects. Poor mold design can lead to issues like warping or inconsistent product quality. Regularly reviewing and adjusting designs based on feedback can lead to better results.

Finally, don’t underestimate the importance of machine settings. Parameters like temperature, pressure, and cycle time should be monitored closely. A small change can drastically impact product quality. Continuous learning and adjustments are key to mastering the process.

Related Posts

-

2025's Top 5 Innovations in Plastic Injection Molding Manufacturing

-

Exploring Innovative Applications of Thermoplastic Injection Molding in Modern Manufacturing

-

Maximizing Efficiency in Plastic Injection Mold Tooling for High Volume Production

-

2025 How to Choose the Best Plastic Injection Tooling for Your Production Needs

-

2025 Top 5 Innovations in Injection Moulding Process for Efficient Production

-

Understanding the Science Behind Plastic Injection Molding for Innovative Manufacturing Solutions