Maximizing Efficiency in Plastic Injection Mold Tooling for High Volume Production

In the competitive landscape of manufacturing, maximizing efficiency in plastic injection mold tooling has become critical for achieving high volume production. According to a report by Allied Market Research, the global plastic injection molding market is projected to reach $300 billion by 2025, underscoring the immense potential for businesses to optimize their tooling processes. Efficient plastic injection mold tooling not only reduces cycle times but also enhances product quality and consistency, which are vital for meeting the increasing demands of various industries. As the trend towards automation and smart manufacturing accelerates, industry experts predict that companies embracing cutting-edge technologies in mold design and production will see substantial gains in operational efficiency and cost-effectiveness. This article aims to explore essential tips and strategies that can significantly enhance the efficiency of plastic injection mold tooling, ensuring manufacturers stay ahead in this rapidly evolving market.

Leveraging Advanced Materials for Enhanced Mold Performance

In the realm of plastic injection mold tooling, the choice of materials plays a critical role in maximizing efficiency and performance. Leveraging advanced materials such as high-performance alloys, reinforced thermoplastics, and composites significantly enhances the durability and thermal stability of molds. These innovative materials not only withstand the rigorous demands of high-volume production but also reduce the frequency of mold maintenance and replacements, ultimately leading to lower operational costs.

Moreover, the integration of advanced materials can improve the precision of mold design, allowing for tighter tolerances and better surface finishes in the final products. Materials that offer superior heat resistance and thermal conductivity can optimize the cooling processes, dramatically shortening cycle times. By adopting these advanced solutions, manufacturers can achieve a competitive edge, ensuring their production lines operate with maximum efficiency while delivering high-quality output.

Integrating Automation Technologies in Injection Mold Tooling Processes

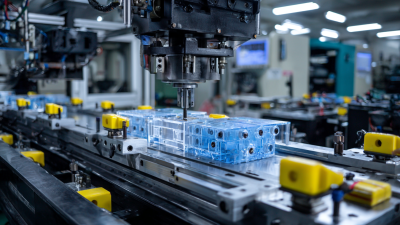

In the fast-paced world of manufacturing, integrating automation technologies into injection mold tooling processes can significantly enhance efficiency and reduce production costs. Automation systems, such as robotic arms and automated material handling, streamline the workflow, allowing for quicker mold changes and reducing production downtime. By leveraging these technologies, manufacturers can achieve higher precision and consistency, ultimately leading to improved product quality and increased output volumes.

Tips: When considering automation, evaluate your current processes to identify bottlenecks. Investing in a programmable logic controller (PLC) system can provide greater control over the entire injection molding operation, facilitating real-time adjustments and monitoring.

Moreover, the use of smart sensors and IoT devices can provide invaluable data feedback from the molding process. This data can be analyzed to optimize conditions and anticipate maintenance needs before equipment failures occur. Implementing predictive maintenance not only extends the life of tooling but also ensures continual high-volume production without unplanned interruptions.

Tips: Utilize data analytics to track production metrics continually. This practice not only enhances operational efficiency but also empowers your team to make informed decisions based on real-time data insights.

Implementing Data Analytics for Predictive Maintenance in Production

The adoption of Industry 4.0 technologies is revolutionizing the manufacturing landscape, particularly in the realm of predictive maintenance. By leveraging data analytics, manufacturers can harness real-time data to optimize production processes, enhance quality, and significantly boost system throughput. The integration of IoT, AI, and cloud computing enables a new level of interaction with big data, allowing companies to anticipate maintenance needs and minimize downtime. This proactive approach not only reduces operational costs but also drives overall efficiency in production lines.

The predictive maintenance market is expected to experience substantial growth, with projections indicating it will surpass $14.31 billion by 2025 and exceed $20.5 billion by 2035, reflecting a compound annual growth rate (CAGR) of over 30.5%. Companies are increasingly recognizing the value of AI in streamlining maintenance strategies, creating opportunities for continuous improvement. As predictive maintenance methodologies advance, manufacturers can make informed decisions based on data-driven insights, transforming not just maintenance practices but the entire manufacturing ecosystem.

Maximizing Efficiency in Plastic Injection Mold Tooling

This chart displays the predictive maintenance impact on production efficiency over a year. The data shows the percentage of downtime due to maintenance against the number of production cycles.

Streamlining Workflow Processes for Increased Production Output

In today’s competitive manufacturing landscape, streamlining workflow processes is essential for maximizing production output in plastic injection mold tooling. According to a report by Grand View Research, the global plastic injection molding market is expected to reach $352.99 billion by 2025, driven by the increasing demand for lightweight components in various sectors. Efficient workflow not only enhances production speed but also reduces operational costs, ultimately leading to higher profit margins.

One effective strategy for streamlining workflows involves implementing automated systems, which can significantly decrease cycle times. A study from the Society of Plastics Engineers indicates that automation can reduce production time by up to 30%, enabling manufacturers to meet high-volume demands without compromising quality. Additionally, using advanced simulation software for mold design can minimize errors and rework, further optimizing the process. By adopting these practices, manufacturers can achieve a seamless integration of their workflow, ensuring consistent production rates and improved overall efficiency in high-volume plastic injection molding operations.

Optimizing Design for Manufacturability in High Volume Applications

In high-volume production, optimizing design for manufacturability (DFM) is crucial for reducing costs and enhancing efficiency in plastic injection molding. A well-engineered design can streamline the manufacturing process, minimizing the time and resources required for each cycle. This involves selecting appropriate materials and ensuring that the design adheres to industry standards, which can significantly impact the overall performance of the mold and the quality of the final product.

Key practices in optimizing DFM include simplifying geometric complexity and incorporating features that facilitate easier mold release. The integration of uniform wall thickness, rounded edges, and sufficient draft angles into the design can reduce stress on the molds during production, thereby extending their lifespan and maintaining consistency in the final output. Additionally, engaging in collaborative discussions between design and manufacturing teams early in the product lifecycle can help identify potential challenges and address them proactively, leading to more effective and efficient tooling solutions.

Related Posts

-

7 Essential Tips for Optimizing Your Mold Manufacturing Process

-

Why Understanding Injection Molding Tooling Can Transform Your Manufacturing Success

-

Exploring the Future of Manufacturing: How Plastic Injection Molded Parts Transform Industries

-

Unlocking Efficiency: How Precision Plastic Injection Molded Parts Boost Production by 30% in Manufacturing

-

Exploring Innovative Applications of Thermoplastic Injection Molding in Modern Manufacturing

-

Understanding Best Plastic Manufacturing Standards and Five Key Reasons for Global Buyers