Why Molding Precision is Essential for High-Quality Manufacturing Processes?

The importance of molding precision in high-quality manufacturing processes cannot be overstated. As industries increasingly rely on advanced production techniques, the demand for precision in molding has surged. According to Dr. Jane Thompson, a leading expert in the field of manufacturing engineering, "Molding precision is not just a technical specification; it is the bedrock upon which the quality and efficiency of the entire production process is built." This encapsulation highlights how pivotal molding precision is to achieving optimal manufacturing outcomes.

In a landscape where product quality and performance are non-negotiable, manufacturers must prioritize systems and procedures that ensure precise molding. The implications of inadequate molding precision can ripple through a production line, affecting everything from raw material usage to final product reliability. Thus, as companies strive to enhance their manufacturing capabilities, a concerted focus on molding precision emerges as a fundamental requirement for success.

Ultimately, the pursuit of impeccable molding precision is essential not only for enhancing product quality but also for fostering innovation and competitiveness in the market. As we delve deeper into the nuances of molding precision, it becomes evident that this expertise serves as a crucial determinant of excellence in contemporary manufacturing practices.

The Importance of Precision in Molding for Manufacturing Success

Precision in molding plays a pivotal role in the success of manufacturing processes across various industries. The quality of the final product is heavily dependent on the accuracy and consistency of the molds used during production. A high level of precision ensures that components fit together seamlessly, reducing the risk of defects and enhancing product durability. This directly impacts not only the functionality of the product but also customer satisfaction and brand reputation.

Moreover, the importance of precision in molding extends beyond the immediate manufacturing implications. It influences operational efficiency, as well-formed molds require fewer adjustments and repairs, ultimately reducing production downtime. Additionally, precise molding contributes to cost-effectiveness by minimizing material waste and rework, thereby optimizing resource utilization. In a competitive market where stakeholders demand excellence, achieving precision in molding is integral to driving operational success and maintaining a competitive edge.

Key Factors Affecting Precision in Molding Processes

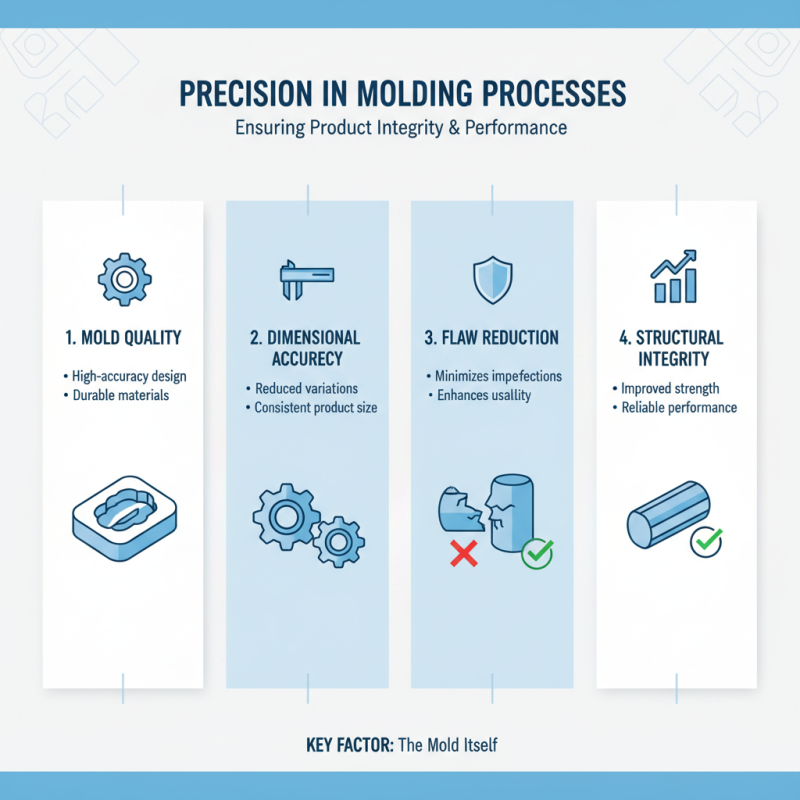

Precision in molding processes is vital for ensuring the integrity and performance of manufactured products. Several key factors play a crucial role in achieving this precision. One primary factor is the quality of the mold itself. Molds that are designed with high accuracy and constructed from durable materials can significantly reduce variances in the dimensions of the final product. Any imperfections within the mold can translate into flaws in the finished items, impacting their usability and structural integrity.

Another essential factor is the control of process parameters during molding. Variables such as temperature, pressure, and injection speed must be meticulously monitored to maintain consistency throughout production. Fluctuations in these parameters can lead to defects like warping or incomplete filling, which compromise the overall quality of the output. Additionally, the skill level of the operators overseeing the molding process can greatly influence precision. Trained personnel who understand the nuances of the equipment and materials are better equipped to make real-time adjustments, ensuring that the production process remains as precise and efficient as possible.

Impact of Molding Precision on Product Quality and Performance

Molding precision plays a crucial role in determining the overall quality and performance of manufactured products, particularly in industries such as automotive, aerospace, and electronics. According to a report by the American Society for Quality, nearly 70% of product failures can be traced back to poor manufacturing processes, which includes inadequate molding precision. This underscores the need for manufacturers to invest in precise molding techniques to ensure that their products meet rigorous quality standards and consumer expectations.

The impact of molding precision extends beyond mere aesthetics; it significantly influences the functional attributes of a product. For instance, components produced with high precision exhibit better dimensional accuracy, which can lead to improved fit, reduced wear, and enhanced performance over the product's lifecycle. A 2022 study published in the Journal of Manufacturing Science and Engineering found that products created with a molding tolerance of ±0.01 mm showed a 25% increase in operational efficiency compared to those with broader tolerances. This finding highlights that precise molding not only elevates product reliability but also contributes to cost reductions, as manufacturers can decrease wastage and rework associated with flawed components.

Industry Standards and Metrics for Assessing Molding Precision

Molding precision is crucial in high-quality manufacturing processes, as it directly influences product reliability, functionality, and overall performance. Industry standards play a significant role in assessing and maintaining this precision. According to the Society of Plastics Engineers (SPE), a variation in dimensional tolerances exceeding 0.005 inches can lead to substantial impacts on part fit and assembly. This precision is paramount in sectors such as automotive and aerospace, where even minute deviations can compromise safety and functionality.

Metrics such as the Cpk (Process Capability Index) are integral in evaluating molding processes. A Cpk value of 1.33 is generally accepted as the minimum standard in many industries, indicating that the process is capable of producing parts within specification limits consistently. Furthermore, the American National Standards Institute (ANSI) emphasizes the importance of implementing continuous improvement practices and integrating statistical process control (SPC) to monitor molding precision effectively. Such metrics assure manufacturers that their processes meet stringent requirements and ultimately satisfy customer expectations for quality and performance.

Case Studies: Precision Molding Trends in High-Quality Manufacturing

Precision molding plays a crucial role in the manufacturing sector, particularly in high-quality production. Recent case studies highlight the rising demand for precision molding techniques across various industries, such as automotive, aerospace, and consumer electronics. In these sectors, the tolerance for defects is exceptionally low. For example, a case study in the automotive industry illustrated how implementing precision molding reduced material waste and improved assembly times, showcasing the impact of enhanced accuracy on overall manufacturing efficiency.

Another notable trend emerged from a case study in the aerospace field, where precision molding significantly contributed to achieving tighter specifications for critical components. Manufacturers utilized advanced molding technology to produce complex geometries with exceptional detail and minimal variability. This not only ensured compliance with stringent safety standards but also allowed for innovations in design that were previously unattainable. The outcomes indicate that investing in precision molding not only elevates product quality but also fosters innovation, making it a vital strategy for manufacturers aiming to maintain competitiveness in the high-quality manufacturing landscape.

Why Molding Precision is Essential for High-Quality Manufacturing Processes? - Case Studies: Precision Molding Trends in High-Quality Manufacturing

| Case Study | Industry | Precision Level (mm) | Production Rate (units/hr) | Quality Rating (out of 10) |

|---|---|---|---|---|

| Case Study A | Automotive | 0.02 | 150 | 9.5 |

| Case Study B | Consumer Electronics | 0.01 | 200 | 9.8 |

| Case Study C | Medical Devices | 0.005 | 80 | 9.9 |

| Case Study D | Aerospace | 0.015 | 100 | 9.7 |

| Case Study E | Industrial Equipment | 0.03 | 120 | 9.3 |

Related Posts

-

Mastering Precision Tooling Techniques for Maximum Efficiency and Quality

-

What is the Impact of Medical Injection Molding on Healthcare Innovation and Patient Outcomes

-

7 Essential Tips for Optimizing Your Mold Manufacturing Process

-

Why Understanding Injection Molding Tooling Can Transform Your Manufacturing Success

-

Maximizing Efficiency in Plastic Injection Mold Tooling for High Volume Production

-

2025 How to Choose the Best Plastic Injection Tooling for Your Production Needs