How to Optimize Injection Molding Tolerances for Enhanced Product Quality and Precision

In the competitive landscape of manufacturing, optimizing injection molding tolerances has emerged as a critical factor influencing product quality and precision. According to a report by the Association for Manufacturing Technology, the global injection molding market is expected to reach $300 billion by 2025, driven by demand for greater accuracy in component manufacturing. The significance of tight injection molding tolerances cannot be overstated, as even minor deviations can lead to expensive rework and quality issues, ultimately impacting a company's bottom line.

A study conducted by the Plastics Industry Association highlights that nearly 70% of manufacturers attribute product defects to inadequate tolerances, emphasizing the need for refined processes and standards. By adopting best practices in defining and managing injection molding tolerances, companies can enhance their product integrity, reduce waste, and meet stringent regulatory requirements, positioning themselves for success in an ever-evolving market.

Strategies for Defining Injection Molding Tolerances Based on Material Properties

Defining injection molding tolerances is crucial for ensuring product quality and precision, especially when considering the specific material properties in use. According to a report by the American Society of Mechanical Engineers (ASME), tolerances can significantly impact the manufacturability and performance of molded parts. For instance, parts molded with high-performance polymers such as PEEK can achieve tighter tolerances, often within ±0.005 inches, which is essential for applications in the aerospace and medical industries where precision is paramount.

Material selection also plays a vital role in determining tolerances. Research from the Society of Plastics Engineers indicates that the thermal expansion properties of materials can lead to dimensional variations during the cooling process. By understanding these characteristics, manufacturers can implement strategies such as compensating for shrinkage and adjusting cooling times, thereby optimizing the tolerances based on material behavior. Furthermore, using advanced simulation tools can help predict how different materials will react during the molding process, aiding in the refinement of tolerances tailored to each specific application.

Optimization of Injection Molding Tolerances Based on Material Properties

This bar chart illustrates the optimal tolerances for various injection molding materials. By selecting appropriate tolerances based on material properties, manufacturers can enhance product quality and precision.

Utilizing CAD Software for Precision Tolerance Calculations in Injection Molding

In the realm of injection molding, achieving optimal tolerances is crucial for enhancing product quality and precision. Utilizing CAD software for precision tolerance calculations can significantly streamline the design process, ensuring that each dimension adheres to specified limits. This approach not only minimizes errors during the manufacturing phase but also facilitates better communication among design and engineering teams. By integrating advanced CAD tools, you can visualize how tolerances affect part assemblies and make informed adjustments early in the design stage.

Tips: Always set up a detailed tolerance analysis in your CAD software right at the beginning of the design process. This will help to identify potential issues before they escalate. Additionally, consider embracing sensitivity analyses to see how changes in one component affect the overall assembly. Regularly updating your CAD models with real-world data will also improve accuracy and help maintain high standards of product quality.

To further enhance precision, it’s important to familiarize yourself with the specific limitations of your injection molding process. Each material and machine will have its own set of operational tolerances, and understanding these can aid in setting realistic expectations for product performance. By leveraging CAD software alongside thorough knowledge of these parameters, manufacturers can fine-tune their designs to achieve exceptional results.

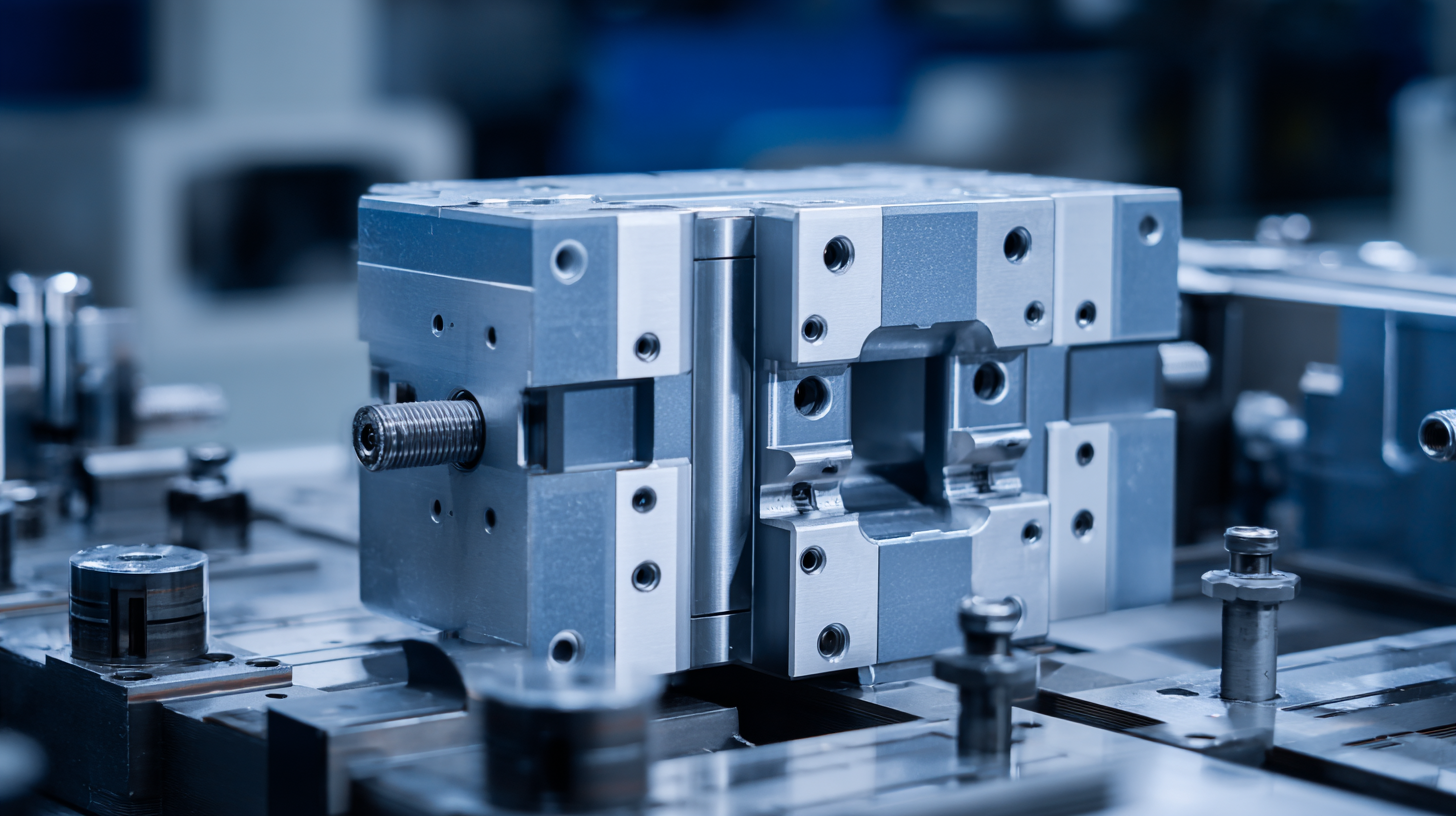

Best Practices for Designing Mold Geometry to Improve Tolerance Control

Designing mold geometry is crucial to optimize injection molding tolerances, which directly impacts both product quality and precision. One of the key considerations is the selection of proper draft angles. Incorporating adequate draft angles helps facilitate the easy removal of parts from the mold, minimizing the risk of damaging the product while also ensuring a good dimensional fit.

Tips: Always aim for a draft angle of at least 1-2 degrees for standard materials, and adjust based on the complexity of the part.

In addition, it is important to consider the wall thickness of the molded parts. Uniform wall thickness helps prevent warpage and ensures even cooling, which leads to better tolerances. If varying thickness is unavoidable due to design constraints, gradual transitions should be implemented to help manage stress distributions within the part.

Tips: Analyze your design for areas that can be made uniform and consult material data sheets for optimal thickness recommendations to enhance tolerance control.

Impact of Temperature and Pressure on Injection Molding Tolerances and Final Product Quality

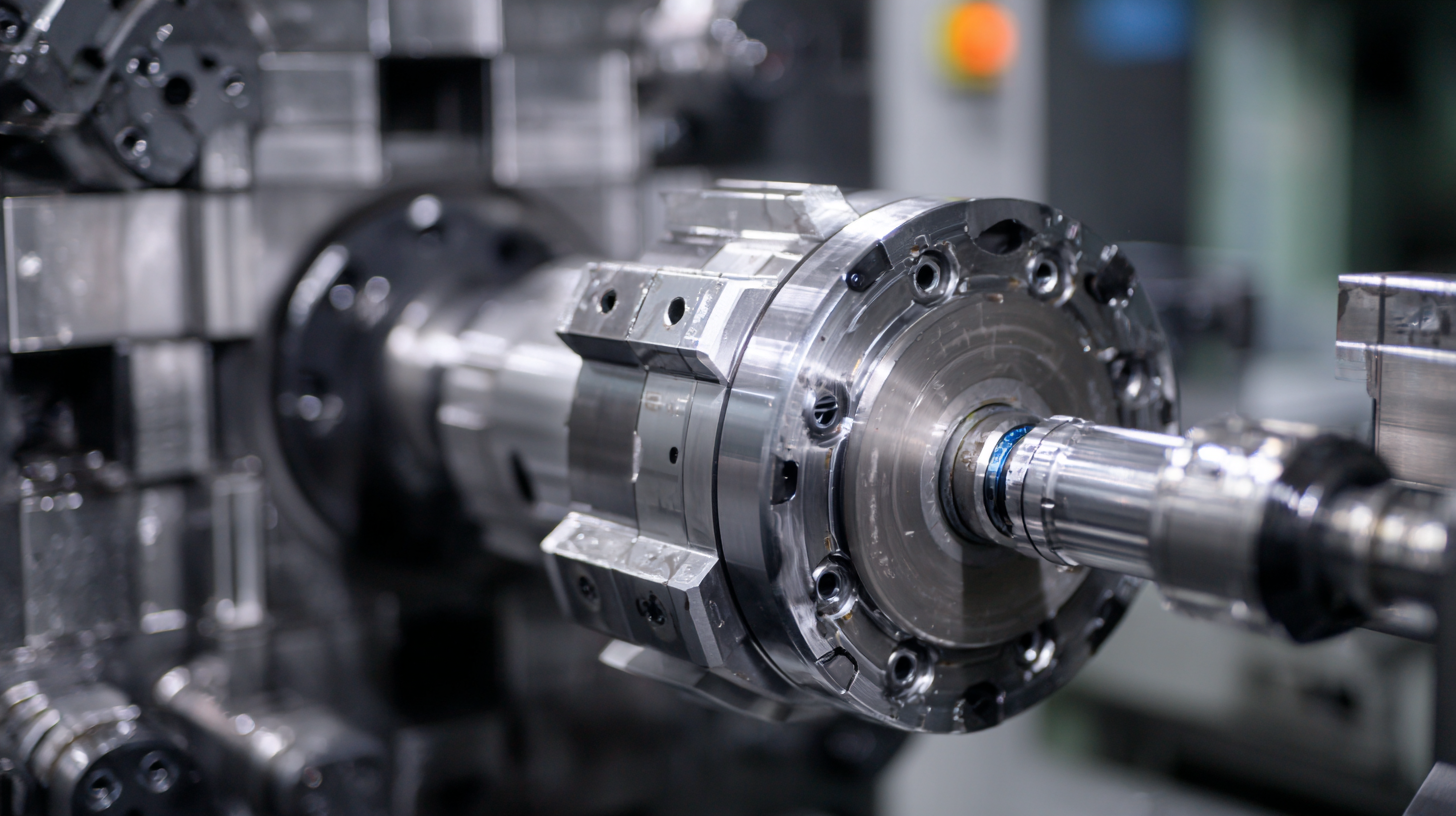

The impact of temperature and pressure on injection molding tolerances is crucial for achieving high product quality and precision. Temperature plays a significant role in the viscosity of the molten material. If the temperature is too low, the material may not flow properly, leading to incomplete fills and poor surface finishes. Conversely, excessively high temperatures can result in degradation of the polymer, adversely affecting its mechanical properties. Maintaining an optimal temperature range is vital for ensuring consistent flow and achieving tight tolerances.

Pressure is another key factor in the injection molding process. Appropriate injection pressure ensures that the molten material fills the cavity completely and compactly. Insufficient pressure can cause voids and sink marks, while excessive pressure may lead to increased wear on the mold and potential dimensional inaccuracies due to overpacking. By carefully controlling both temperature and pressure throughout the molding process, manufacturers can enhance tolerances, reduce scrap rates, and ultimately improve the overall quality of the final product.

How to Optimize Injection Molding Tolerances for Enhanced Product Quality and Precision

| Parameter | Optimal Range | Impact on Tolerance | Final Product Quality |

|---|---|---|---|

| Injection Temperature | 180-230°C | Critical - High temperature reduces viscosity for flow | Improved surface finish and dimensional accuracy |

| Injection Pressure | 800-1500 bar | High - Ensures complete filling and reduces voids | Consistent wall thickness and minimized defects |

| Cooling Time | 30-60 seconds | Moderate - Affects shrinkage and tolerance | Enhances dimensional stability after ejection |

| Material Viscosity | Low to Medium | Essential - Affects melt flow and packing | Key to achieving fine details and features |

Implementing Statistical Process Control for Monitoring Injection Molding Tolerances

Statistical Process Control (SPC) is essential for monitoring injection molding tolerances, ensuring that product quality and precision are consistently met throughout production runs. In recent developments, cavity pressure-based methods have emerged as a way to adjust holding pressure dynamically, addressing the variances in cavity pressure distribution during each shot. By implementing this technique, manufacturers can significantly enhance the consistency of their injection molding quality, reducing the likelihood of defects and maintaining tighter tolerances.

Moreover, the integration of data-driven approaches for predicting quality deterioration offers a proactive strategy to manage and optimize processes effectively. Automated prediction models can alert operators to potential issues before they escalate, allowing adjustments to be made in real time. This, combined with advanced monitoring technologies, ensures that manufacturers can maintain high standards of precision while accommodating the increasing demands from design engineers for improved performance in plastic optics and other applications. Engaging in these strategies not only fosters better quality outcomes but also supports a more efficient manufacturing process overall.

Related Posts

-

Innovative Examples of Automotive Injection Molding Applications in the Industry

-

Unlocking the Secrets of Best Plastic Manufacturing with Comprehensive Technical Guidelines

-

What is the Impact of Medical Injection Molding on Healthcare Innovation and Patient Outcomes

-

Essential Checklist for Quality Assurance in Plastic Injection Molded Parts Production

-

Leading Chinese Factory Delivers Unmatched Excellence in Medical Injection Molding

-

5 Expert Tips for Optimizing Your Metal Injection Mold Design