Unlocking Efficiency: How Precision Plastic Injection Molded Parts Boost Production by 30% in Manufacturing

In today's competitive manufacturing landscape, enhancing operational efficiency is paramount for sustaining growth and profitability. Plastic injection molded parts play a crucial role in achieving this objective, as they allow manufacturers to produce high-quality components with remarkable precision and consistency. According to a report by MarketsandMarkets, the global plastic injection molding market is projected to reach $418.3 billion by 2026, growing at a CAGR of 5.8%. This growth underscores the increasing reliance on plastic injection molded parts as an essential solution for reducing production costs and improving turnaround times. By leveraging advanced technologies and refined processes, manufacturers can boost production efficiency by up to 30%, thereby optimizing resource utilization and meeting the dynamic demands of the market. As we explore the intricacies of how precision plastic injection molded parts contribute to enhanced manufacturing performance, it becomes evident that these components not only drive productivity but also foster innovation across various industries.

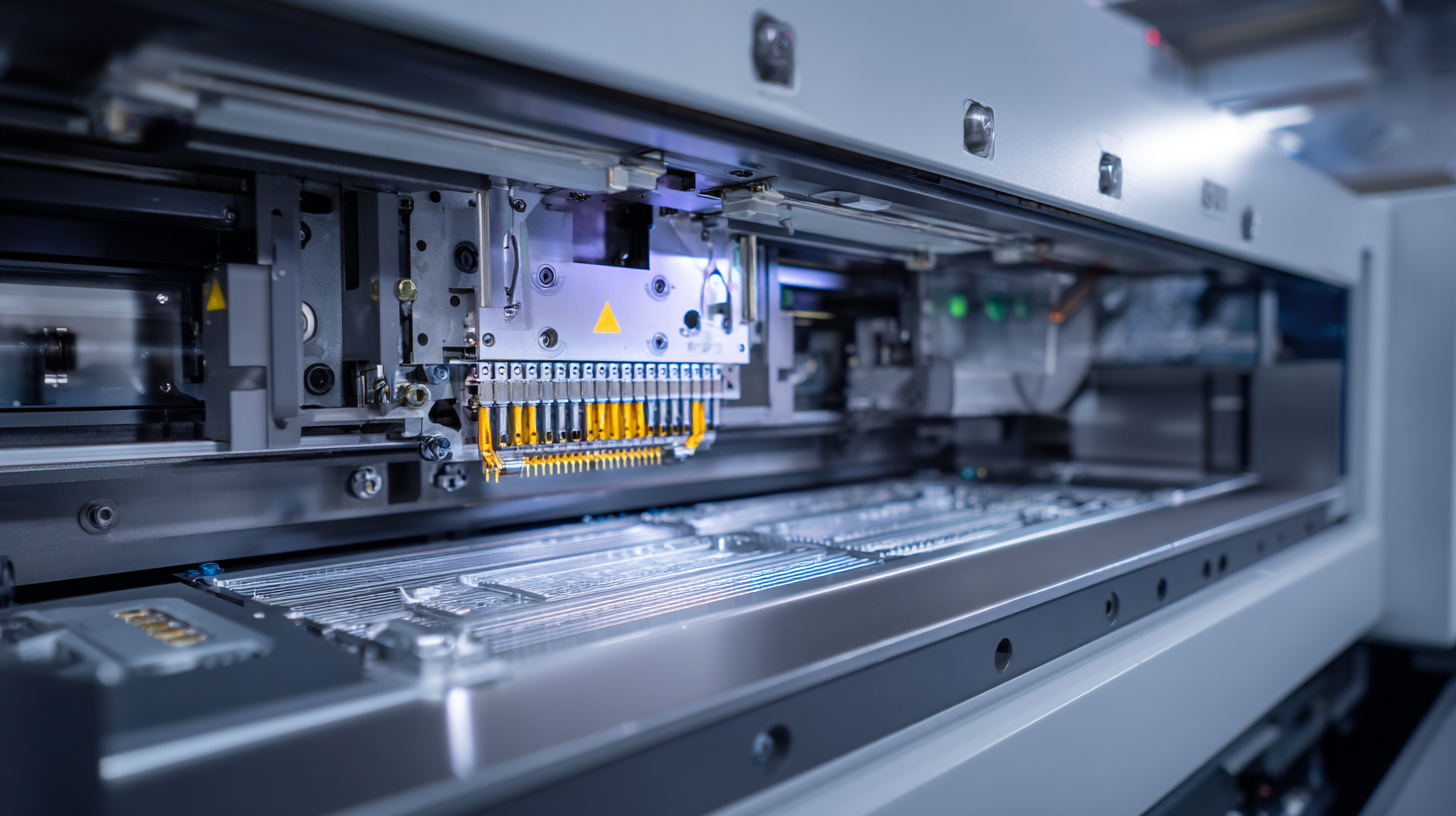

Revolutionizing Manufacturing Processes with Precision Plastic Injection Molding

Precision plastic injection molding is revolutionizing manufacturing processes by enhancing efficiency and precision across various industries. According to a report by Grand View Research, the global injection molding market is projected to reach $440 billion by 2025, driven largely by advancements in technology and the increasing demand for precise components. The ability to create intricate designs and consistent quality at high volumes has made precision plastic injection molding a favoured choice for manufacturers aiming to optimize their production lines.

One significant advantage of precision molding is its capacity to reduce waste and lower production costs. The efficient use of materials reduces scrap rates, which, according to an analysis by the American Injection Molding Institute, can cut costs by up to 30%. Additionally, the speed of the injection molding process allows companies to respond more swiftly to market demands, further enhancing production capabilities. As manufacturers seek innovative solutions to remain competitive, the adoption of precision plastic injection molded parts positions them to significantly boost efficiency and profitability in an ever-evolving market.

Quantifying the Production Boost: A 30% Increase Explained

Precision plastic injection molded parts have become pivotal in enhancing manufacturing efficiency, resulting in a significant production boost estimated at around 30%. According to a study by the American Society for Plastic Engineers, manufacturers utilizing precision molding techniques achieve not only faster cycle times but also greater part consistency. This efficiency is crucial in industries such as automotive and electronics, where the demand for high-quality components is relentless.

The impact of this increased efficiency can be quantified in various ways. A report from Deloitte indicates that companies implementing precision plastic parts see a reduction in material waste by up to 15%, which translates to lower production costs. Furthermore, the ability to produce complex geometries with tight tolerances allows for fewer assembly steps, thereby streamlining the production process. This means that manufacturers can respond more swiftly to market demands, enhancing their competitive edge while maintaining high standards of quality and sustainability.

The Role of Customization in Enhancing Efficiency through Injection Molding

Customization plays a vital role in enhancing efficiency through injection molding, as it allows manufacturers to tailor components specifically to their production needs. This bespoke approach enables the creation of parts that fit precisely into assembly lines, minimizing the time and effort required for adjustments and reducing the likelihood of errors during integration. By focusing on unique specifications and optimizing designs for specific function, manufacturers achieve smoother operations and reduced rework time, further driving productivity.

Moreover, custom injection molded parts can significantly streamline supply chains. With the ability to produce components that meet exact requirements, manufacturers can enhance compatibility across various systems, reducing the need for multiple suppliers or off-the-shelf parts that may not be optimized for their applications. This not only leads to more efficient production cycles but also maintains consistent quality standards, as the parts are designed and made to endure rigorous performance criteria. As a result, the adoption of customized injection molding solutions becomes a strategic advantage in the competitive manufacturing landscape.

Streamlining Supply Chains with Advanced Injection Molded Components

In today's competitive manufacturing landscape, streamlining supply chains has become essential for enhancing productivity and reducing costs.

Advanced injection molded components play a crucial role in this transformation by enabling faster production cycles and minimizing material waste.

With precision plastic injection molding, manufacturers can produce complex shapes and high-tolerance parts, thereby reducing the need for extensive secondary processing and assembly.

This capability not only improves the efficiency of the production line but also accelerates time-to-market for end products.

Furthermore, the use of advanced injection molded parts fosters greater collaboration within supply chains.

By providing manufacturers with reliable, uniform components, businesses can standardize their operations and simplify inventory management.

This uniformity eliminates the discrepancies that often arise from sourcing parts from multiple suppliers, leading to a more cohesive production strategy.

Ultimately, these streamlined processes result in significant cost savings and enhanced operational flexibility, allowing manufacturers to respond swiftly to changing market demands.

Future Trends: Innovations in Plastic Injection Molding for Greater Productivity

Innovations in plastic injection molding are rapidly transforming the manufacturing landscape, with significant advancements designed to enhance productivity. A 2022 report from MarketsandMarkets indicates that the global plastic injection molding market is projected to reach $452.6 billion by 2028, growing at a CAGR of 5.4%. This growth is propelled by the adoption of advanced technologies such as automation and Industry 4.0 practices, which enable manufacturers to optimize their production processes, increase efficiency, and reduce waste.

One of the most notable trends is the integration of smart technologies, including Internet of Things (IoT) sensors and artificial intelligence (AI) analytics, into injection molding machines. According to a study by Protolabs, manufacturers utilizing these advanced systems can achieve a 20-30% increase in operational efficiency. For instance, real-time monitoring allows for immediate adjustments based on production data, minimizing downtime and material defects. Additionally, advancements in mold design and materials—such as the use of lightweight, high-strength composites—are contributing to a more streamlined manufacturing process, further enhancing output without compromising quality.

Related Posts

-

How to Identify Top Suppliers for Optimal Injection Molding Mold Design

-

Essential Checklist for Quality Assurance in Plastic Injection Molded Parts Production

-

Exploring the Future of Manufacturing: How Plastic Injection Molded Parts Transform Industries

-

Exploring the Role of Import and Export Certifications in Best Mold Manufacturing

-

5 Expert Tips for Optimizing Your Metal Injection Mold Design

-

What is the Impact of Medical Injection Molding on Healthcare Innovation and Patient Outcomes