Top 10 Injection Tooling Techniques for Enhanced Manufacturing Efficiency

In the ever-evolving landscape of manufacturing, efficiency remains paramount as companies strive to optimize production processes. Injection tooling has emerged as a critical technique in enhancing production efficiency, allowing manufacturers to produce high-quality components with speed and precision. According to a recent report by the International Plastics Manufacturers Association, businesses leveraging advanced injection tooling methods have seen a productivity increase of up to 30%, significantly reducing operational costs while maintaining product integrity.

Industry experts recognize the transformative impact of injection tooling on manufacturing. Dr. Emily Carter, a leading figure in plastics engineering, states, "Adopting innovative injection tooling techniques is no longer a choice but a necessity for companies aiming to stay competitive in today's market." Her insights highlight the urgency for manufacturing firms to embrace these advancements, as failing to innovate could result in lost market opportunities.

As we explore the top 10 injection tooling techniques, we will delve into how these methods not only streamline operations but also contribute to sustainability initiatives by minimizing waste and energy consumption. Understanding and implementing these strategies can equip manufacturers with the tools needed to thrive in an increasingly competitive industry.

Top Injection Tooling Techniques for Enhanced Manufacturing Efficiency

When aiming to enhance manufacturing efficiency, the injection tooling process plays a pivotal role. Adopting advanced injection tooling techniques can significantly streamline production, reduce waste, and improve product quality. One effective approach is to implement modular tooling systems, which allow for quicker adjustments and variations in production runs. This not only saves time on changeovers but also minimizes downtime, enabling manufacturers to respond swiftly to market demands.

Additionally, the integration of smart technology into injection molding processes can lead to remarkable efficiency gains. By using sensors and data analytics, manufacturers can monitor equipment performance in real-time, identifying potential issues before they escalate into costly downtimes. This proactive maintenance approach ensures that the production process remains uninterrupted, maintaining high throughput and consistent quality.

Tips for enhancing efficiency in injection tooling often include focusing on the materials used. Opt for high-quality raw materials that reduce cycle times and enhance durability. Regular training for staff on the latest tooling techniques and technologies is crucial, ensuring that everyone is equipped with the skills to maximize production efficiency. Lastly, consider conducting periodic audits of the tooling process to identify inefficiencies and areas for improvement, paving the way for continual enhancements in your manufacturing operations.

Overview of Injection Tooling Techniques in Modern Manufacturing

Injection tooling is a crucial aspect of modern manufacturing that directly impacts efficiency, product quality, and operational costs. With advancements in technology and materials, manufacturers are continually exploring innovative techniques to optimize their injection processes.

Techniques such as multi-cavity molds, rapid prototyping, and hot runner systems are at the forefront of this evolution, enabling manufacturers to increase production rates while enhancing product performance.

When considering injection tooling techniques, it's essential to focus on materials and design. Utilizing advanced materials that reduce wear and deformation can lead to longer-lasting molds and lower maintenance costs. Additionally, employing design software to simulate the injection process can help identify potential issues, such as air traps or poor flow, before production begins.

Tips: Always conduct thorough research on the tooling materials and designs that best suit your production needs. Regular maintenance of molds can also prevent costly downtime and ensure consistent output quality.

Consider integrating automation in the inspection and quality control processes; this can significantly reduce human error and improve overall manufacturing efficiency. By adopting these strategies, manufacturers can stay competitive in an ever-evolving landscape.

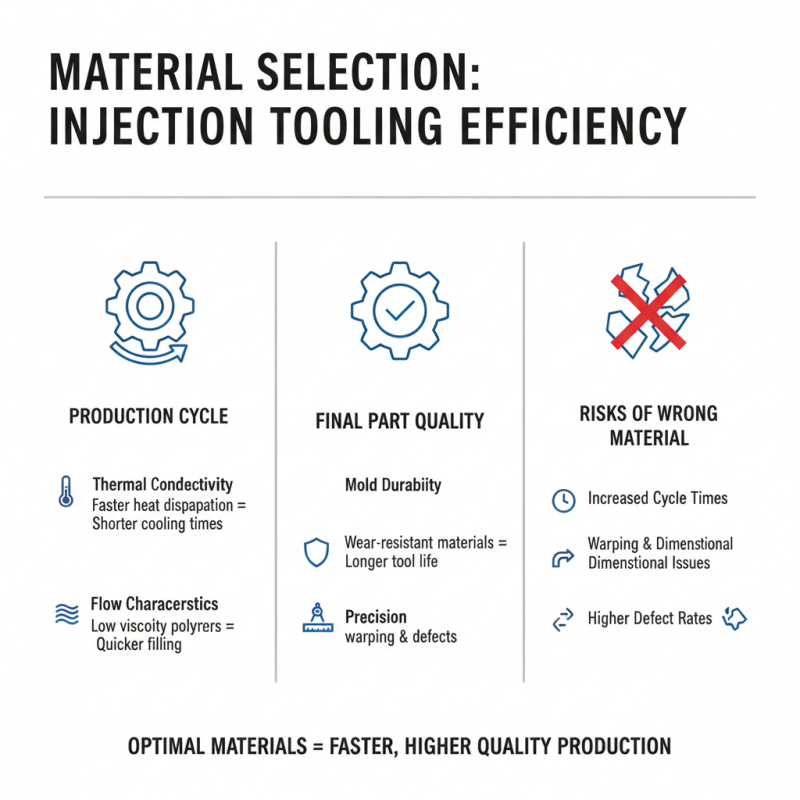

The Role of Material Selection in Injection Tooling Efficiency

Material selection plays a pivotal role in injection tooling efficiency, influencing both the production cycle and the final quality of the manufactured parts. The choice of materials affects thermal conductivity, flow characteristics, and mold durability, which in turn impacts cycle times and precision. For example, high-performance polymers may provide enhanced flow and lower viscosity, facilitating quick filling and reducing waste. Conversely, selecting the wrong material can lead to complications such as warping, increased cycle times, and higher defect rates.

Tips: When selecting materials for injection tooling, consider the specific requirements of the end application. Factors such as temperature resistance, tensile strength, and chemical compatibility should guide your choices. Additionally, evaluating the material’s flow properties can optimize processing speeds and improve overall efficiency. Engage in thorough testing to understand how different materials behave under various conditions, ensuring that your tooling process can meet desired production standards without compromising quality.

Another important factor is the compatibility of the selected materials with the tooling process itself. Inserts, coatings, and surface treatments can significantly enhance the lifespan and output of injection molds. For instance, using specialized coatings can minimize wear and improve demoldability, which is essential for maintaining production rates. Always assess the comprehensive performance of materials in conjunction with tooling technology to achieve the best results in efficiency and cost-effectiveness.

Enhancing Cycle Times with Advanced Mold Design Techniques

In the realm of manufacturing, enhancing cycle times is paramount for improving overall efficiency. Advanced mold design techniques play a crucial role in achieving this goal. By integrating features such as conformal cooling channels and optimized gate placements, manufacturers can significantly reduce the time molds spend in cooling and increase the speed of production. These innovations not only shorten cycle times but also ensure a more uniform temperature distribution during the molding process, which contributes to higher-quality outputs.

**Tip:** When designing molds, consider implementing cooling channels that follow the contours of the part. This design strategy can minimize temperature differences across the mold, leading to shorter cooling times and greater uniformity in the final product.

Another effective approach to enhance manufacturing efficiency is through simulation technology. By utilizing advanced simulation software, manufacturers can predict and analyze potential issues in the mold design phase. This proactive approach enables engineers to make necessary adjustments before physical production begins, saving valuable time and resources.

**Tip:** Invest in simulation tools to visualize and optimize the mold flow and cooling strategies before actual implementation. This foresight can drastically reduce trial-and-error phases in mold production, leading to faster cycle times and enhanced productivity.

Top 10 Injection Tooling Techniques for Enhanced Manufacturing Efficiency

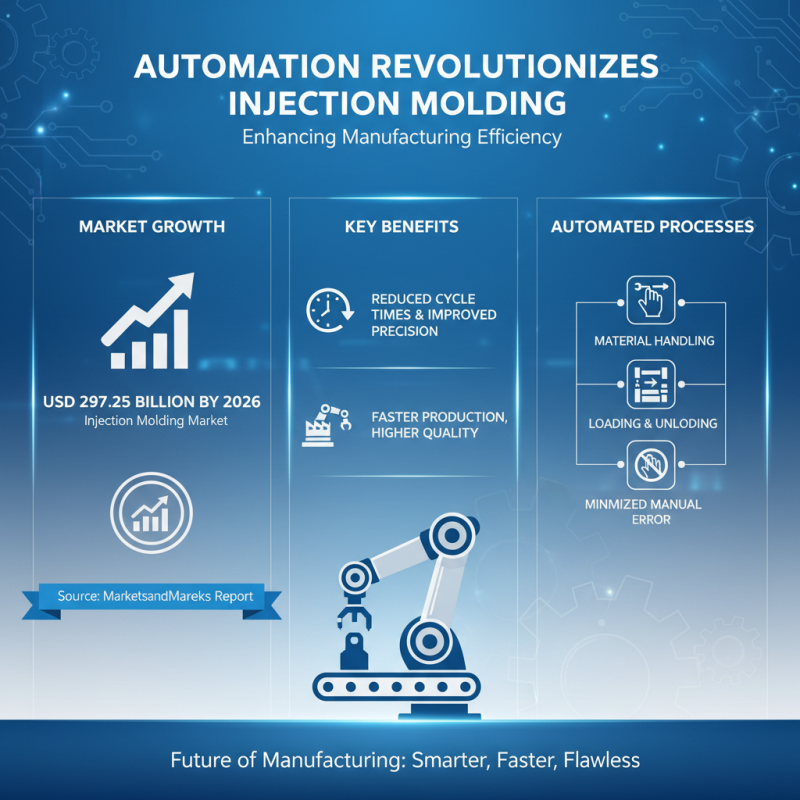

Automation and Robotics in Injection Molding Processes

In recent years, the integration of automation and robotics in injection molding processes has significantly enhanced manufacturing efficiency. According to a report by MarketsandMarkets, the injection molding market is projected to reach USD 297.25 billion by 2026, with automation technologies playing a pivotal role in this growth. By incorporating robotic systems, manufacturers can reduce cycle times and improve precision, allowing for faster production rates without compromising quality. More specifically, automated systems can streamline material handling, loading, and unloading, minimizing manual intervention and potential errors.

Furthermore, the use of robotics in injection molding extends beyond mere efficiency gains. A study published in the Journal of Automation and Robotics highlights that advanced robotic systems can perform complex tasks such as part assembly and quality inspection at a fraction of the time required by human operators. These technologies not only boost productivity but also facilitate real-time monitoring and data collection, enabling manufacturers to make informed decisions based on performance metrics. By leveraging automation, businesses in the injection molding sector can achieve greater consistency in their processes while significantly reducing labor costs, setting the stage for a new era of smart manufacturing.

Conclusion

The article "Top 10 Injection Tooling Techniques for Enhanced Manufacturing Efficiency" explores various methodologies that improve the efficiency of injection tooling in modern manufacturing. It begins with an overview of key techniques that have evolved, emphasizing the critical role of material selection in achieving optimal results. Advanced mold design techniques are highlighted as essential for reducing cycle times, while the integration of automation and robotics is presented as a significant factor in streamlining the injection molding process.

Furthermore, the article showcases industry case studies that provide metrics for success, illustrating how the adoption of these advanced injection tooling techniques can lead to significant improvements in productivity and cost-effectiveness. By leveraging these strategies, manufacturers can enhance their operations and maintain competitiveness in the ever-evolving market landscape.

Related Posts

-

Why Understanding Injection Molding Tooling Can Transform Your Manufacturing Success

-

How to Choose the Best US Injection Molding Solutions for Your Manufacturing Needs

-

What is the Impact of Medical Injection Molding on Healthcare Innovation and Patient Outcomes

-

Exploring Innovative Applications of Thermoplastic Injection Molding in Modern Manufacturing

-

2025 Top 5 Innovations in Injection Moulding Process for Efficient Production

-

2025's Top 5 Innovations in Plastic Injection Molding Manufacturing