2025's Top 5 Innovations in Plastic Injection Molding Manufacturing

In the rapidly evolving landscape of plastic injection molding manufacturing, staying ahead of the curve is essential for competitive advantage. According to a report by the International Plastics Industry Association, the plastic injection molding market is expected to reach $450 billion by 2025, driven by innovations that enhance efficiency and sustainability. As the industry leans toward advanced technologies such as automated setups, 3D printing integration, and innovative materials, companies must adapt their strategies to leverage these advancements.

Industry expert Dr. Maria H. Gonzalez, a leading analyst at the Plastics Technology Center, emphasizes the importance of innovation in this sector: “The future of plastic injection molding manufacturing is not just about producing parts; it is about embracing technologies that revolutionize the way we think about design and material use.” As we look forward to 2025, it is imperative to identify the top innovations that will define the future of this vital manufacturing process. This article explores five key advancements that promise to reshape the plastic injection molding landscape, driving sustainability and efficiency while meeting the growing demands of consumers and industries alike.

Revolutionary Materials: Bio-Based Resins in Injection Molding

The integration of bio-based resins into the injection molding manufacturing process marks a significant leap towards sustainable practices in the industry. As businesses increasingly prioritize environmental responsibilities, the use of bio-resins—often referred to as bio-plastics or bio-polymers—offers a promising alternative to traditional materials.

These not only diminish the reliance on fossil fuels but also align with the broader industry shift towards eco-friendly solutions, making them essential in the development of innovative products.

Recent market insights highlight the growing potential of bio-based materials, particularly bio-polypropylene, which is projected to witness substantial growth in the coming years. Reports indicate that advancements in technology, such as optimized hot runner systems, are enhancing the efficiency and efficacy of bio-resin utilization in injection molding.

As companies, including major brands, experiment with biobased materials in their products, the demand for sustainable packaging and manufacturing processes is set to rise, further propelling the bio-revolution within the plastics industry.

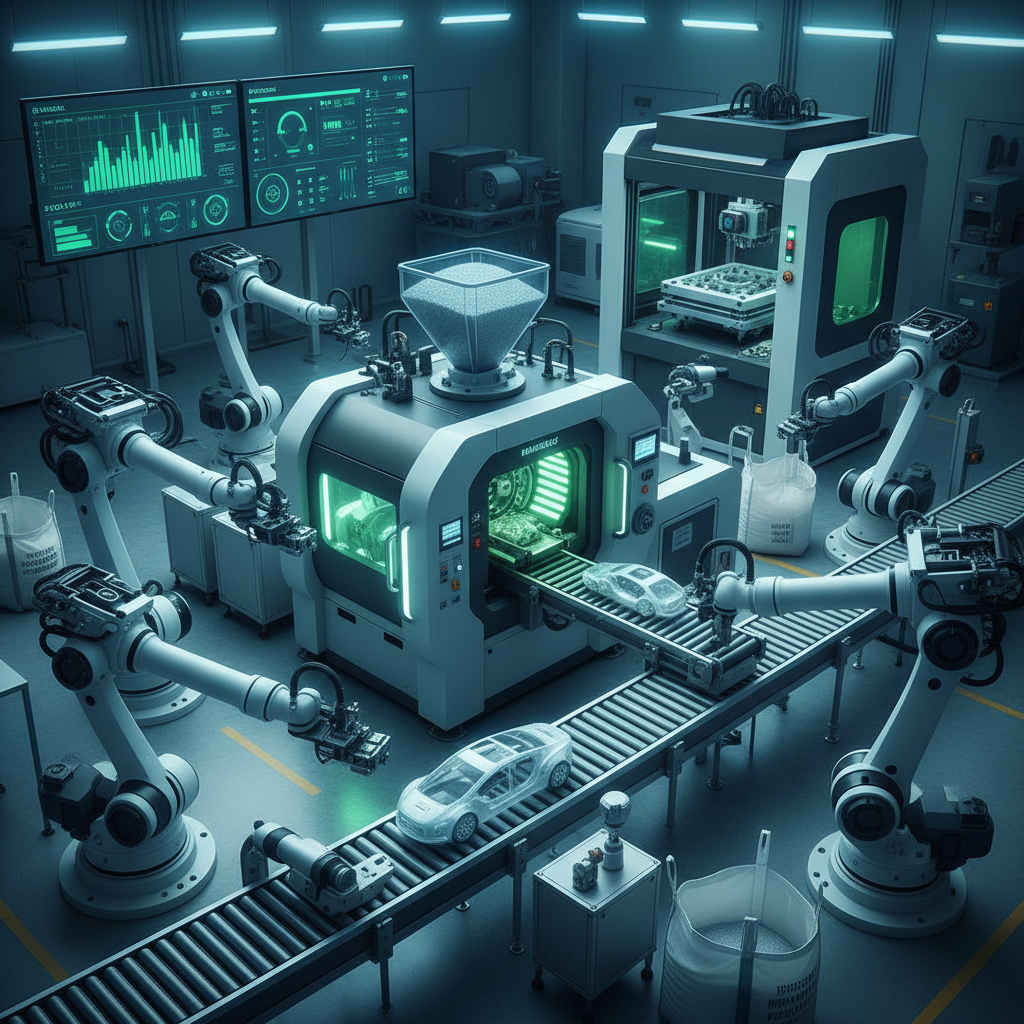

Smart Automation: AI and Robotics Transforming Production Lines

In recent years, the injection molding manufacturing sector has witnessed a significant transformation driven by smart automation technologies, particularly artificial intelligence (AI) and robotics. According to a report by Markets and Markets, the global market for industrial robots in manufacturing is projected to reach $47.16 billion by 2025, showcasing the increasing reliance on automated solutions to enhance production efficiency and precision. This shift is especially pertinent in the plastic injection molding industry, where downtime and material waste can significantly impact profitability.

AI-driven systems are revolutionizing production lines by enabling real-time monitoring and predictive maintenance. A study conducted by McKinsey highlights that implementing AI in manufacturing can increase productivity by up to 20%, reducing operational costs and optimizing resource allocation. Robotics, including collaborative robots (cobots), are also playing a vital role in streamlining workflows and reducing human error. With the ability to perform repetitive tasks tirelessly, these technologies enhance the consistency and quality of molded plastic products, meeting the growing demand for custom and complex components in various industries such as automotive and consumer goods. As the industry advances, the integration of smart automation will undoubtedly become a cornerstone of successful plastic injection molding operations.

2025's Top 5 Innovations in Plastic Injection Molding Manufacturing

Sustainable Practices: Innovations for Reducing Plastic Waste

As the world increasingly recognizes the environmental impact of plastic waste, the plastic injection molding industry is stepping up with innovative sustainable practices. One significant advancement is the development of bio-based plastics. These materials, derived from renewable resources, offer a viable alternative to traditional petroleum-based plastics, drastically reducing the carbon footprint associated with production and disposal.

Another noteworthy innovation is the incorporation of advanced recycling technologies into the injection molding process. By utilizing chemical recycling methods, manufacturers can break down used plastics into their fundamental components, allowing for reuse in new products without compromising quality. This closed-loop system not only minimizes waste but also conserves valuable resources, effectively promoting a circular economy within the industry. Moreover, smart manufacturing techniques, such as process optimization and energy-efficient equipment, further enhance sustainability by reducing energy consumption and waste generation during production.

2025's Top 5 Innovations in Plastic Injection Molding Manufacturing - Sustainable Practices: Innovations for Reducing Plastic Waste

| Innovation | Description | Benefits | Implementation Year |

|---|---|---|---|

| Biodegradable Resins | Development of new biodegradable materials for injection molding. | Reduces environmental impact and enhances recyclability. | 2025 |

| Energy-Efficient Machines | Injection molding machines designed to consume less energy. | Lower operational costs and reduced carbon footprint. | 2025 |

| Recycled Material Integration | Techniques for efficiently using recycled plastics in production. | Promotes circular economy and decreases raw material costs. | 2025 |

| Smart Monitoring Systems | IoT-enabled systems to monitor and optimize production processes. | Increased efficiency and waste reduction. | 2025 |

| Additive Manufacturing Integration | Combining injection molding with 3D printing technologies. | Enhanced design flexibility and material efficiency. | 2025 |

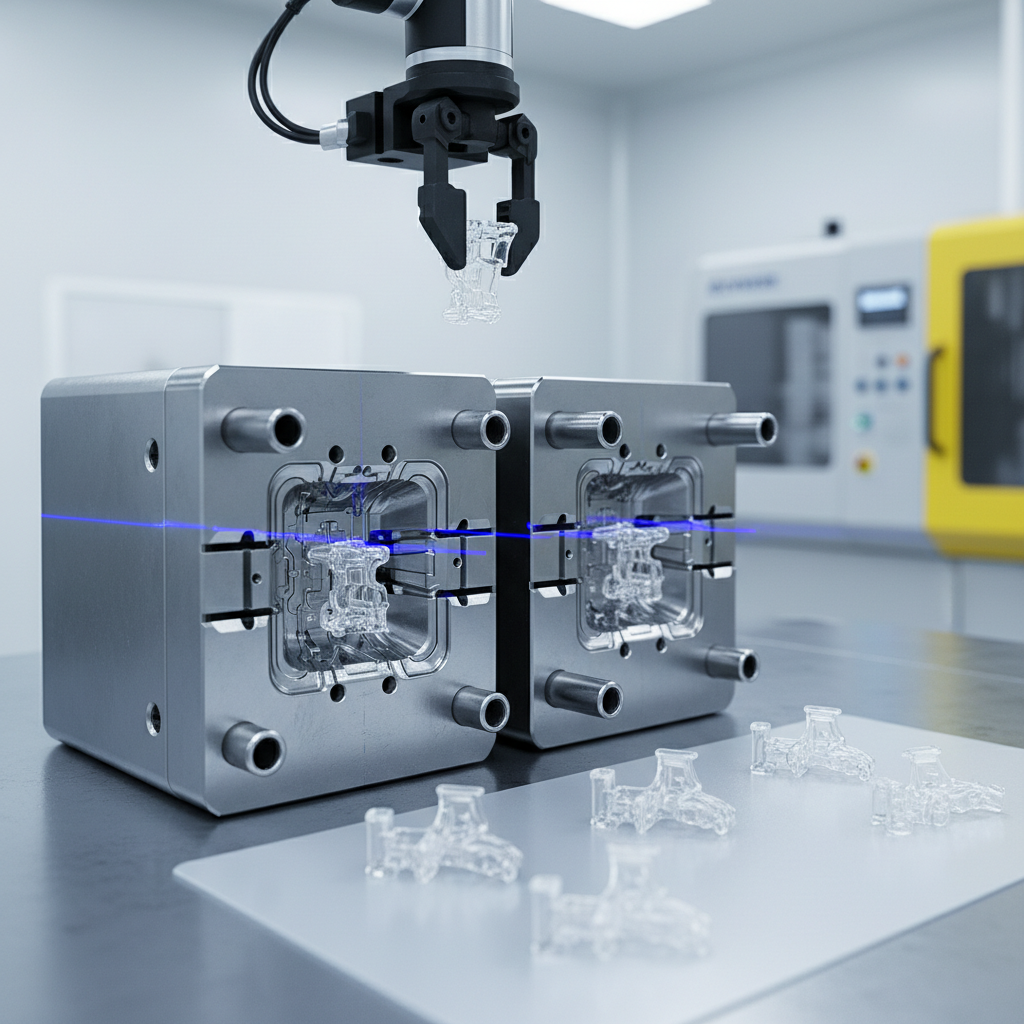

Precision Engineering: Advancements in Mold Design Technology

In recent years, advancements in precision engineering have significantly transformed mold design technology within the plastic injection molding manufacturing industry. The continuous evolution of micro injection molding techniques has opened new avenues for producing intricate components with exceptional accuracy. This heightened precision is vital for applications requiring detailed geometries, especially in sectors like medical devices and microelectronics, where even the slightest deviation can lead to compromised functionality.

Moreover, the integration of advanced materials, such as chalcogenide glass, is further enhancing capabilities in mold design. These materials are paving the way for creating high-performance infrared optics, which are essential for modern applications like thermal imaging in construction and surveying. As the demand for high-quality, precise components grows, the plastic injection molding industry is poised for a remarkable transformation, driven by innovative technologies and materials that improve production efficiency and product performance.

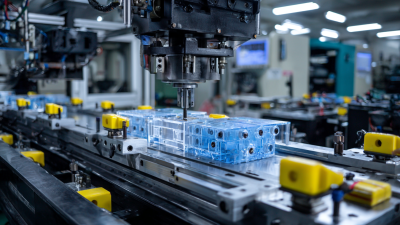

Enhanced Quality Control: IoT and Data Analytics Integration

The integration of IoT and data analytics in the plastic injection molding manufacturing industry is set to enhance quality control significantly by 2025. As highlighted in recent industry reports, the IoT in construction market is expected to grow at a CAGR of over 25% between 2021 and 2026, reflecting the increasing reliance on smart technologies across sectors. In manufacturing, digital twins enable the real-time monitoring of production processes, allowing manufacturers to create dynamic replicas of their operations. This advancement not only improves efficiency but also enhances the quality assurance processes, as manufacturers can quickly identify and rectify defects based on real-time data.

Moreover, business intelligence tools driven by IoT data analytics empower manufacturers to make informed, data-driven decisions. These systems analyze vast datasets from production lines and supply chains, facilitating improvements in quality management and operational efficiency. By 2025, integrating AI into quality control frameworks is projected to further optimize processes, reducing waste and enhancing the overall production quality.

**Tips:**

1. Implement IoT sensors throughout your production line to gather data continuously, ensuring real-time feedback and adjustments.

2. Utilize advanced data analytics tools to identify trends and anomalies in production processes, enabling proactive quality control measures.

Related Posts

-

Unlocking the Secrets of Best Plastic Manufacturing with Comprehensive Technical Guidelines

-

Exploring Innovative Applications of Thermoplastic Injection Molding in Modern Manufacturing

-

Maximizing Efficiency in Plastic Injection Mold Tooling for High Volume Production

-

2025 How to Choose the Best Plastic Injection Tooling for Your Production Needs

-

2025 Top 5 Innovations in Injection Moulding Process for Efficient Production

-

Leveraging Excellent After Sales Support for Cost Effective Future of Best Mold Design in Injection Molding