Top Uses of Stainless Steel Woven Wire Mesh in 2026?

stainless steel woven wire mesh is gaining significant traction across various industries as we approach 2026. According to a recent market analysis by Smith & Johnson Research, the demand for this material is expected to grow by 15% annually. This rapid growth stems from its versatility and durability, particularly in architectural and filtration applications.

Industry expert Dr. Emily Carter highlights this trend, stating, "The adaptability of stainless steel woven wire mesh makes it indispensable for modern construction and safety solutions." Applications range from industrial filters to decorative facades. The material is resilient against corrosion, which ensures longevity in both outdoor and indoor settings.

However, challenges remain. The market faces pricing volatility and supply chain disruptions. Companies manufacturing stainless steel woven wire mesh must focus on sustainability while navigating these hurdles. The potential of this material is tremendous, but reflection on manufacturing processes is essential for a brighter, sustainable future.

Applications of Stainless Steel Woven Wire Mesh in Industrial Sectors

Stainless steel woven wire mesh is a versatile material in various industrial sectors. Its durability and resistance to corrosion make it ideal for demanding environments. In food processing, this mesh provides critical filtration while ensuring hygiene. It helps in separating liquids from solids efficiently.

In the construction industry, stainless steel mesh acts as a reinforcement tool. It supports concrete structures, enhancing strength and stability. However, improper installation can lead to weaknesses. Careful attention to detail is essential here.

Another notable application is in the pharmaceutical sector. Hospitals and laboratories use stainless steel woven mesh for sterilization processes. It ensures that contaminants do not compromise sensitive materials. Yet, a lack of regular maintenance can affect its performance. Operators must remain vigilant.

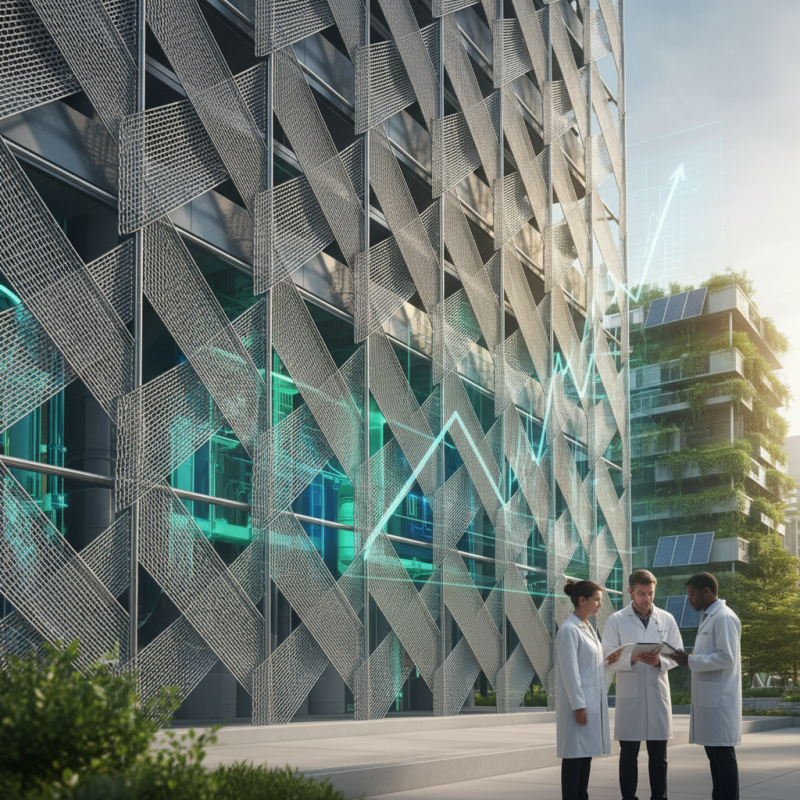

Usage in Architectural and Design Elements for Modern Structures

Stainless steel woven wire mesh is becoming a preferred choice in modern architectural designs. Its durability and versatility allow for unique applications in various structures. Designers often use it for facades, ceilings, and dividers. The mesh integrates both function and aesthetics, enhancing visual appeal while maintaining structural integrity.

In large buildings, the mesh provides an elegant touch. It allows natural light to filter in while offering privacy. This balance is essential in urban environments where space is at a premium. The reflective quality of stainless steel also helps in energy efficiency, further emphasizing its appeal in modern architecture.

Tips: When considering stainless steel mesh, think about the scale of the project. Small installations can create intricate designs, while larger applications can make bold statements. Test samples to see how they interact with light and shadow. Reflect on the mesh's role in the overall design. Will it complement or dominate the surroundings? Such considerations are vital for achieving harmony in modern spaces.

Role in Filtration and Separation Technologies

In 2026, stainless steel woven wire mesh plays a crucial role in various filtration and separation technologies. This versatile material excels in applications requiring high strength and durability. Its corrosion-resistant properties ensure longevity in demanding environments. Industries like water treatment and food processing rely heavily on this mesh for effective filtration. Micron-sized openings capture contaminants efficiently, maintaining product integrity.

Woven wire mesh is not just functional; it also faces challenges. The manufacturing process can sometimes lead to inconsistencies in mesh size or weave tightness. This inconsistency may affect filtration results. Moreover, although stainless steel is resistant to rust, it can still develop surface issues over time. Regular maintenance and monitoring are essential to prevent these problems.

Despite its benefits, selecting the right type of mesh can be daunting. Factors such as material thickness and wire diameter significantly influence performance. Each application has unique requirements, which may not always align perfectly with available options. Understanding these variables is vital for effective separation technology. Organizations must remain diligent in assessing their needs and the mesh's capability. This ongoing evaluation helps improve efficiency and effectiveness in their operations.

Top Uses of Stainless Steel Woven Wire Mesh in 2026

| Application | Material Type | Opening Size (µm) | Typical Use Case | Market Growth (%) |

|---|---|---|---|---|

| Water Treatment | 304 Stainless Steel | 50 | Removal of Suspended Solids | 8.5 |

| Pharmaceuticals | 316L Stainless Steel | 25 | Filtration of Active Ingredients | 10.2 |

| Food Processing | 304 Stainless Steel | 100 | Separation of Food Particles | 7.1 |

| Mining and Minerals | 430 Stainless Steel | 300 | Screening of Minerals | 6.8 |

| Chemical Processing | 316 Stainless Steel | 15 | Separation of Chemical Mixtures | 9.0 |

Impact on Food Processing and Hygiene Standards

In 2026, stainless steel woven wire mesh continues to play a vital role in food processing and hygiene standards. It offers durability and corrosion resistance, making it an ideal choice for environments requiring high sanitation. According to industry reports, the global demand for food-grade stainless steel mesh is expected to grow by 8% annually. This growth emphasizes its indispensable role in modern food safety regulations.

The mesh is essential for filtration and separation in food processing. Whether it's sifting flour or processing dairy products, stainless steel woven wire mesh ensures a hygienic production environment. Its smooth surface minimizes bacterial growth, a crucial factor for maintaining strict hygiene standards. Research indicates that stainless steel surfaces can reduce microbial contamination by up to 99% compared to other materials.

Despite these advantages, there are challenges. Some manufacturers may overlook proper cleaning protocols. This carelessness can lead to contamination risks. In a world that increasingly values food safety, this oversight must be addressed. Continuous training on proper hygiene practices will be necessary to leverage the full benefits of stainless steel woven wire mesh.

Innovations and Future Trends in Stainless Steel Wire Mesh Designs

The stainless steel woven wire mesh market is evolving rapidly. Innovations in design are shaping its future applications. In 2026, we may see advanced weaving techniques enhancing strength and durability. Reports suggest that demand for these meshes will grow by 7.5% annually. These meshes are essential for filtration and separation tasks across various industries.

One exciting trend is the incorporation of nano-coatings. These coatings improve corrosion resistance and self-cleaning properties. This could reduce maintenance costs significantly. Moreover, custom mesh designs tailored to specific applications are on the rise. Manufacturers are using advanced software for precision, enabling them to create unique patterns and sizes.

Tips: When selecting woven wire mesh, consider the material’s thickness and aperture size. These factors impact strength and functionality. Testing mesh performance under real conditions is crucial. Not all innovations are a perfect fit for every application. Always evaluate your specific needs to ensure the best results. Seeking expert opinions can provide valuable insights.

Top Uses of Stainless Steel Woven Wire Mesh in 2026

The chart above illustrates the projected usage of stainless steel woven wire mesh across various industries in 2026. The construction sector is expected to utilize the most, significantly influencing the overall market dynamics, followed by food processing and water filtration applications.