Understanding Best Plastic Manufacturing Standards and Five Key Reasons for Global Buyers

In the rapidly evolving landscape of plastic manufacturing, securing a reliable supplier is crucial for global buyers aiming to maintain competitiveness and ensure quality. According to a recent report by MarketsandMarkets, the global plastic manufacturing market is projected to reach $650 billion by 2025, driven by increasing demand across various sectors, including automotive, packaging, and consumer goods. As manufacturers seek to optimize their supply chains, understanding the best plastic manufacturing standards becomes paramount. Not only do these standards enhance product quality and safety, but they also facilitate compliance with international regulations, thereby mitigating risks associated with sourcing. In an industry where the stakes are high, knowing how to identify a quality supplier can be the difference between success and failure, making this a critical focus for any buyer in today's market.

Best Practices in Plastic Manufacturing: A Comprehensive Overview

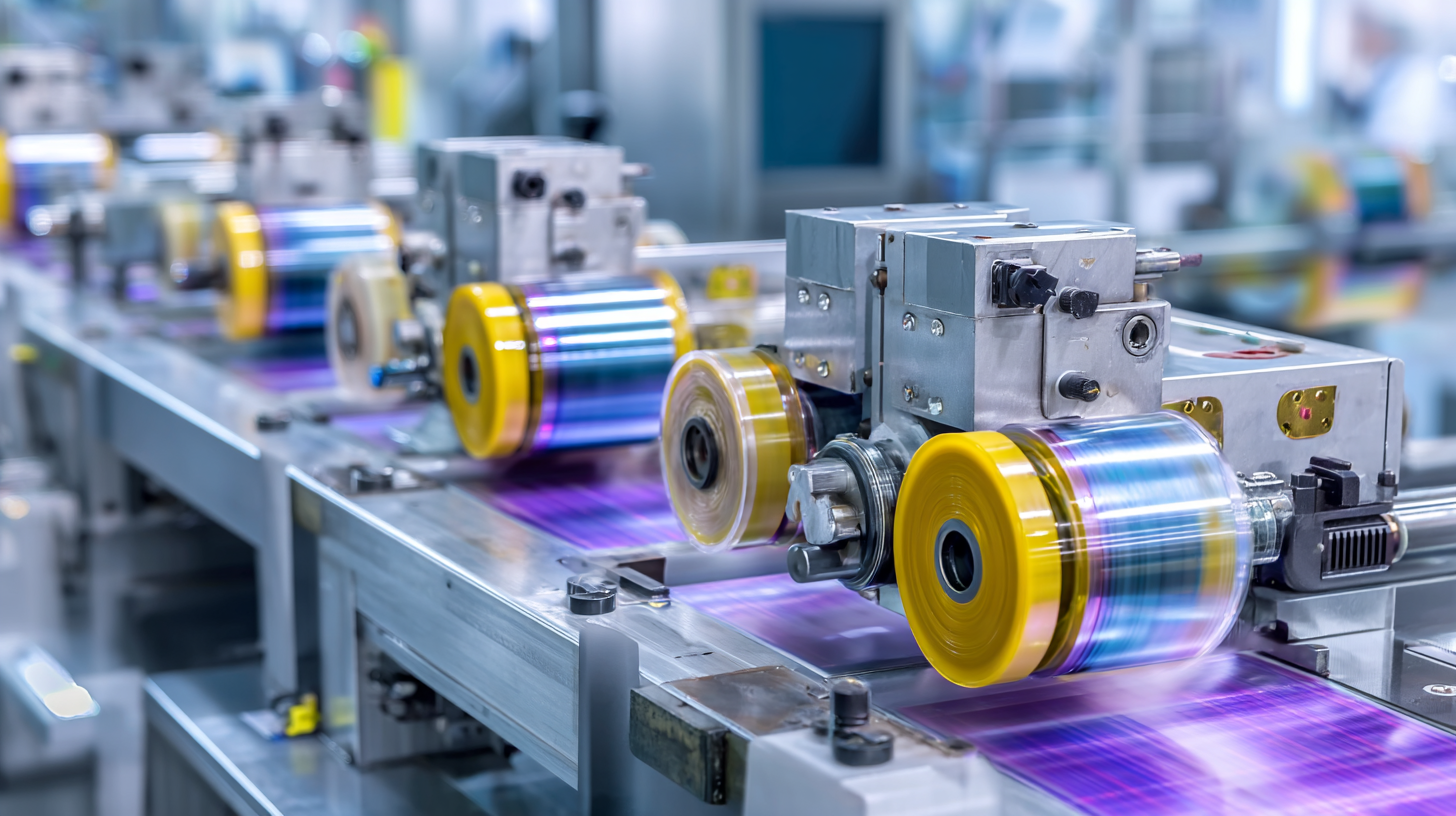

In the ever-evolving world of plastic manufacturing, adhering to best practices is essential to maintain quality and efficiency. A comprehensive overview of these practices reveals the importance of precision engineering, responsible sourcing of materials, and stringent quality control measures. By implementing these standards, manufacturers can not only enhance their production processes but also ensure compliance with global regulations.

Tips for improving plastic manufacturing include investing in advanced machinery and automation to streamline production. This not only boosts efficiency but also reduces the risk of human error. Additionally, fostering a culture of continuous improvement among staff can lead to innovative solutions and enhanced product quality. Finally, regular training sessions on the latest technologies and safety standards can significantly benefit employees and the organization as a whole.

Another vital aspect is sustainable practices. Manufacturers should aim to minimize waste through practices such as recycling and using eco-friendly materials. This commitment to sustainability not only improves the company's image but also appeals to an increasingly environmentally-conscious consumer base, thereby driving growth in a competitive market. By focusing on these essential best practices, plastic manufacturers can position themselves as leaders in the industry.

Key Manufacturing Standards that Global Buyers Should Know

Understanding the best plastic manufacturing standards is crucial for global buyers looking to ensure high-quality products. Key manufacturing standards include ISO 9001, which focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. Another important standard is ISO 14001, which addresses environmental management, helping companies reduce their environmental impact while maintaining efficiency in operations. Compliance with these standards not only enhances product reliability but also boosts brand reputation in the competitive global market.

Furthermore, adhering to specific industry standards such as ASTM, UL, and FDA regulations is essential for manufacturers dealing with specific applications like medical devices or electrical components. These standards guide companies in material selection, testing protocols, and safety requirements, providing a framework for quality assurance. For global buyers, understanding these standards helps in assessing suppliers and making informed decisions, ensuring that products not only meet their expectations but also comply with international safety and environmental criteria.

Understanding Best Plastic Manufacturing Standards and Five Key Reasons for Global Buyers

| Standard Name | Description | Industry Application | Certification Authority |

|---|---|---|---|

| ISO 9001 | Quality management systems – Requirements | All industries | International Organization for Standardization (ISO) |

| ISO 13485 | Quality management systems for medical devices | Medical devices | International Organization for Standardization (ISO) |

| REACH | Registration, Evaluation, Authorisation and Restriction of Chemicals | Chemical and plastic industries | European Chemicals Agency (ECHA) |

| RoHS | Restriction of Hazardous Substances | Electronics and electrical equipment | European Union (EU) |

| ASTM D6400 | Standard specification for labeling of plastics designed to be aerobically composted in municipal or industrial facilities | Compostable plastics | ASTM International |

Exploring the Benefits of After-Sales Support in Plastic Production

In the highly competitive realm of plastic manufacturing, after-sales support plays a crucial role in ensuring a seamless experience for global buyers. This support encompasses everything from troubleshooting issues with products to providing essential maintenance tips, significantly enhancing the overall customer satisfaction. Successful manufacturers understand that their responsibility does not end at the sale; they invest in after-sales services to foster long-term relationships with clients.

One essential tip for buyers is to select manufacturers that provide robust after-sales support, as this can aid in quick resolution of any issues that may arise. Additionally, regular communication with the manufacturer post-purchase can lead to valuable insights about product usage and maintenance, ultimately prolonging the lifespan of the products.

Moreover, training sessions offered as part of after-sales support can empower buyers to maximize the utility of their plastic products. It’s beneficial for buyers to inquire about these training opportunities, ensuring they are well-equipped to handle the products efficiently. By emphasizing after-sales communication and support, manufacturers can significantly enhance their reputation and foster loyalty among global buyers.

Reducing Maintenance Costs: Strategies for Effective Plastic Solutions

When considering plastic solutions for various applications, one significant aspect that cannot be overlooked is maintenance costs. Effective strategies for reducing these costs largely revolve around selecting the right materials and manufacturing standards. By adhering to established plastic manufacturing standards, companies can ensure that their products are durable, reliable, and specifically tailored to withstand challenging operating conditions. This leads to fewer breakdowns, lower repair costs, and extended product lifespans.

Another crucial strategy for lowering maintenance expenses lies in the proactive approach to design and usage. By choosing plastics engineered for specific performance attributes such as UV resistance, chemical compatibility, and impact strength, organizations can minimize the risk of damage over time. Furthermore, implementing regular assessment protocols to monitor the condition of plastic components can help identify potential issues before they escalate, saving both time and resources in the long run. By focusing on these effective plastic solutions, businesses can significantly reduce maintenance costs while improving overall operational efficiency.

Future Trends in Plastic Manufacturing: Innovations on the Horizon

The landscape of plastic manufacturing is rapidly evolving, driven by technological advancements and increasing environmental awareness. One significant trend on the horizon is the adoption of smart manufacturing technologies. Industry 4.0, with its emphasis on automation, the Internet of Things (IoT), and data analytics, is transforming traditional manufacturing processes. These innovations not only enhance efficiency and reduce waste but also enable manufacturers to achieve real-time monitoring of production lines, ensuring higher quality control and faster turnaround times.

The landscape of plastic manufacturing is rapidly evolving, driven by technological advancements and increasing environmental awareness. One significant trend on the horizon is the adoption of smart manufacturing technologies. Industry 4.0, with its emphasis on automation, the Internet of Things (IoT), and data analytics, is transforming traditional manufacturing processes. These innovations not only enhance efficiency and reduce waste but also enable manufacturers to achieve real-time monitoring of production lines, ensuring higher quality control and faster turnaround times.

Moreover, sustainable practices are becoming a hallmark of the plastic manufacturing industry. The push for biodegradable and recyclable materials is more robust than ever, as consumers and regulatory bodies demand greener alternatives. Innovations in bioplastics, derived from renewable resources, and advances in recycling technologies are key developments that will shape the future of plastic production. By prioritizing sustainability, manufacturers can not only meet regulatory requirements but also cater to the rising consumer preference for eco-friendly products, positioning themselves favorably in the global market.